AI Chip Empowerment | OPT Smart Code Reader Enhances Traceability in Photovoltaic Material Production

Driven by the global low-carbon environmental protection trend, the photovoltaic industry has been experiencing rapid growth. The substantial market demand has spurred the advancement of intelligent manufacturing within the industry, making meticulous traceability management across every production stage all the more crucial.

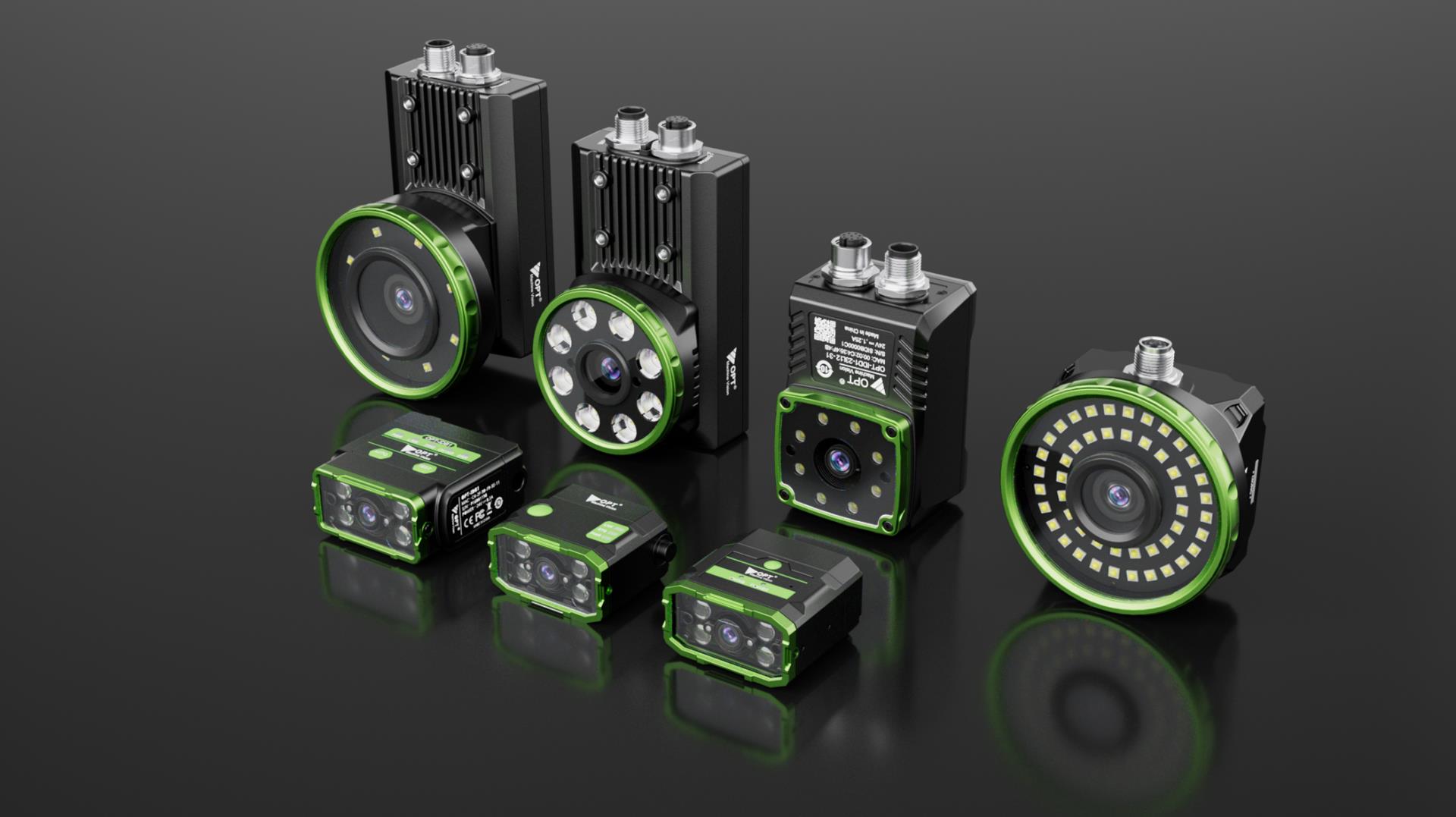

OPT, driven by a profound understanding of industry requirements, has seamlessly integrated its smart code readers into various process stages, such as silicon wafer production, slicing, cell manufacturing, and module assembly, to achieve all-process information traceability. Taking the photovoltaic module production process as an illustrative example, OPT's smart code reader effectively addresses challenges in reading barcodes during processes like film lamination, heat pressing, and laminating.

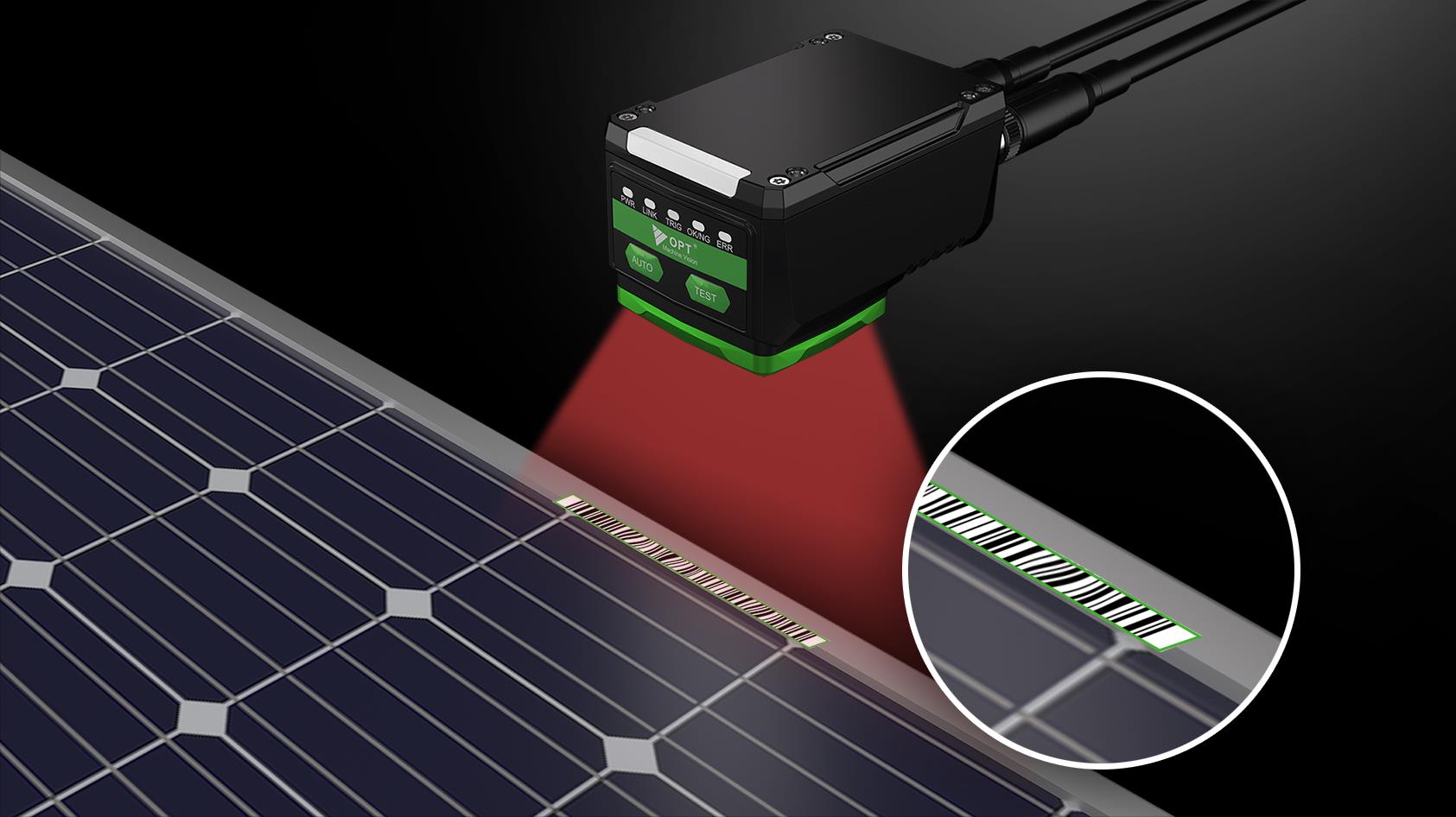

Challenge 1: Blurred Barcodes and Background Pattern Interference

Prior to the lamination process, photovoltaic modules are often coated with EV film of varying thicknesses to protect them. Barcodes on the surface, post-lamination, are susceptible to blurring effects, and the patterns on the photovoltaic panel can bear a resemblance to the numeric character "1" in one-dimensional codes, making them prone to decoding errors. Furthermore, after lamination, photovoltaic modules may produce debris that distorts the barcodes, rendering conventional algorithms inadequate for precise barcode information retrieval.

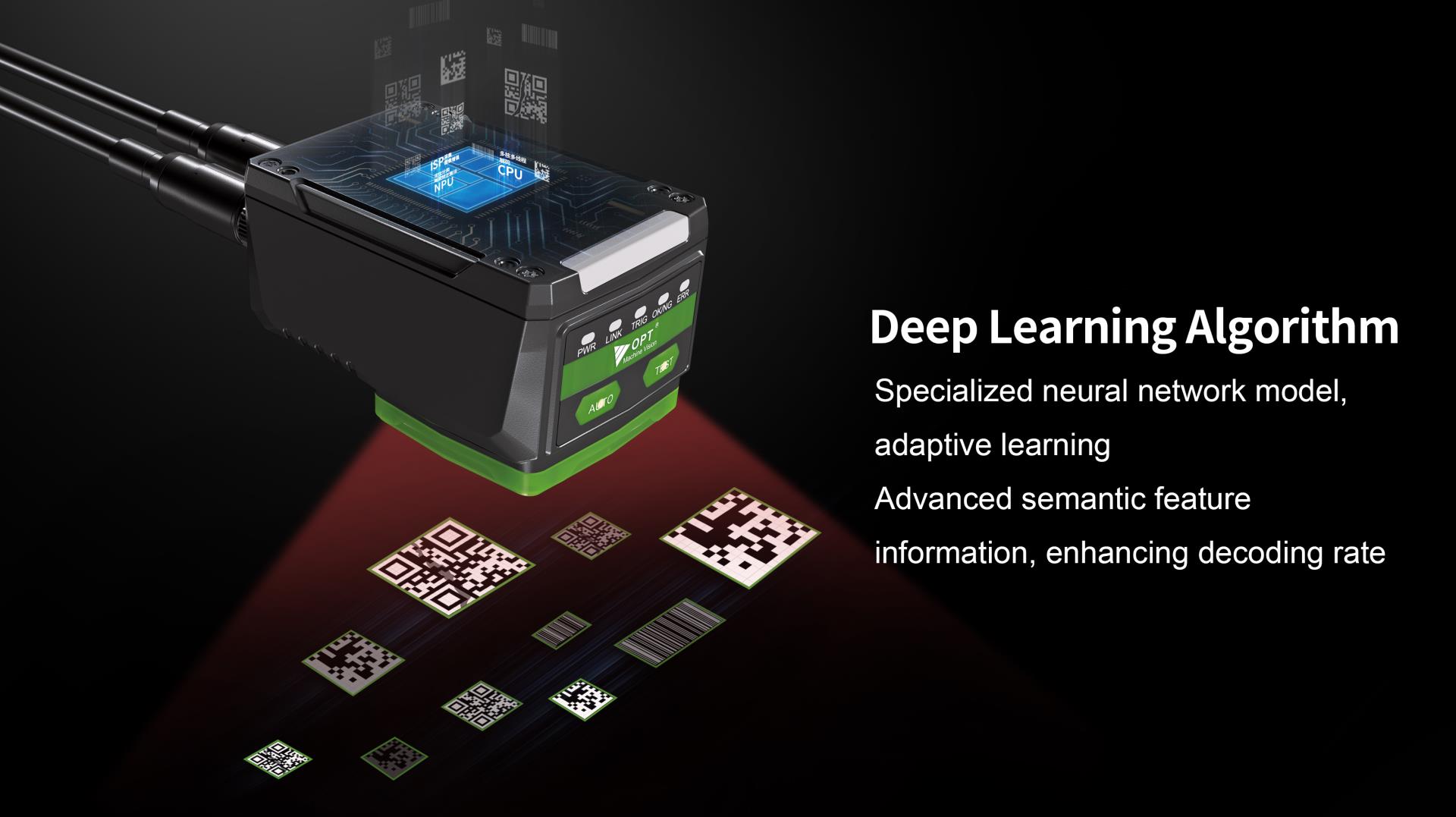

Solution: Embedded AI Chip

OPT Smart Code Reader incorporates an embedded AI chip that, through pre-learning from an extensive dataset of barcode samples, autonomously distinguishes barcode components, characters, and anomalies. Its robust anti-interference algorithm significantly enhances reading rates in complex scenarios. Furthermore, it supports error code filtering, ensuring accurate barcode reading even in the presence of blurred barcodes and background pattern interference. The smart code reader can effectively decode barcodes on photovoltaic modules, accommodating varying thicknesses and styles of EV film, achieving a reading rate of up to 100%.

Challenge 2: Reading Barcodes Susceptible to Glass Reflection

At the lamination station, barcodes are either affixed to the glass surface of photovoltaic modules, making them susceptible to background glare, or some barcodes are directly laser-engraved onto the module's surface, resulting in significant reflection interference and increased difficulty in reading.

Solution: Equipped with Polarizing Filters

To address barcodes affected by reflection interference, OPT smart Code Reader is equipped with polarizing filters. These filters effectively eliminate the impact of glare noise, ensuring that the captured barcode images are clear and evenly lit, thereby enhancing barcode reading accuracy.

Challenge 3: Barcode Distortion

After undergoing the heat pressing process, barcodes on the surface of photovoltaic panels can be susceptible to deformation due to high temperatures, resulting in a lower reading rate.

Solution: Built-in Distortion Correction Algorithm

OPT smart Code Reader features a built-in distortion correction algorithm that automatically rectifies distortions. This ensures accurate barcode information retrieval, even when the barcodes have undergone deformation.

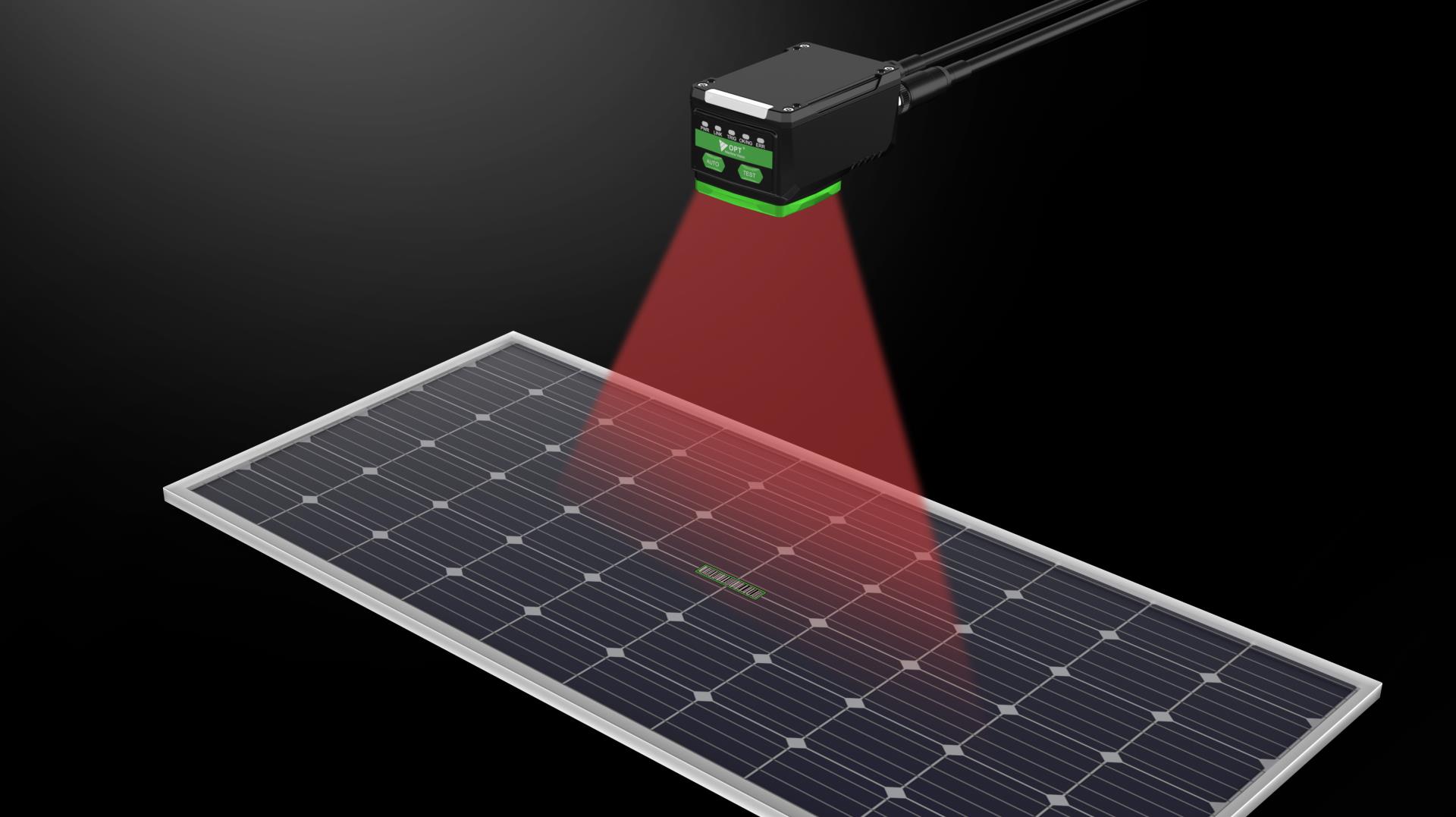

Challenge 4: Inconsistent Barcode Placement

Due to the larger dimensions of photovoltaic modules, barcode placement tends to be more random, increasing the likelihood of missed readings. This presents significant challenges in terms of the reader's field of view and imaging quality.

Solution: Wide Field of View and High Pixel Count

OPT smart Code Reader offers optional ultra-wide-angle lenses, providing a larger field of view. Coupled with high-resolution and highly sensitive image sensors, it ensures clear imaging while effectively suppressing noise interference. Even with a wide field of view and relatively short exposure times, it still delivers bright and clear images, mitigating the occurrence of missed or misread barcodes.

Challenge 5: High-Speed Dynamic Barcode Reading

As photovoltaic module production processes continue to advance, production line speeds have increased significantly. Current mainstream equipment can achieve speeds of up to 1 meter per second (1m/s), necessitating even higher efficiency in barcode reading.

Solution: Multi-Core Heterogeneous Computing and Three-Level Pipeline Software Architecture

To effectively address high-speed dynamic barcode reading scenarios, OPT Smart Code Reader utilizes multi-core heterogeneous computing and a three-level pipeline software structure. This parallel processing approach involving ISP (Image Signal Processor), NPU (Neural Processing Unit), and CPU (Central Processing Unit) accelerates the entire process from image capture to decoding, eliminating the need for delays and enhancing decoding efficiency.

Furthermore, OPT Smart Code Reader can be equipped with a global shutter sensor, achieving frame rates of up to 60 frames per second (fps) and capturing dynamic barcodes at speeds of up to 3 meters per second (3m/s). This aligns perfectly with the high-speed production demands of photovoltaic modules.

Beyond barcode reading applications in photovoltaic module manufacturing processes, OPT smart Code Reader excels in accurately and efficiently reading barcodes on silicon wafers with minute codes, laser-engraved codes on glass surfaces, and more.

EN

EN CN

CN JP

JP