Deep fusion of multi-dimensional vision technology - OPT solved the multi-process detection problem of lithium industry

Lithium industry has entered a round of upgrading cycle. The production demand of refinement and specialization is getting more and more obvious. From the former section of the pole piece manufacturing, to the middle section of the bare core welding, to the core assembly laminating, more efficient, more accurate visual inspection technology are required.

As a global core supplier of lithium vision solutions, OPT's vision application has covered the whole process of lithium battery production, and through the deep integration of 2D, 3D and deep learning multi-dimensional vision technology, it has overcome the industry's inspection difficulties in key processes, such as the edge burr detection of the pole piece, the welding appearance of the pole lugs, the appearance of the blue film of the electric core inspection etc. It has realized the major breakthrough of zero leakage detection and extreme low misjudgment.

01 Pole Piece Burr Detection

zero defect-leakage detection

In the process of manufacturing pole pieces, such as roll pressing, slitting, cutting and other processes, in addition to the detection and monitoring of positive and negative pole surface defects, a real-time online detection of transverse and longitudinal burrs to the edge of the pole piece is needed. The current speed of mainstream equipment on production line is up to 120m/min, which raises a great challenge to the machine vision detection accuracy and response time.

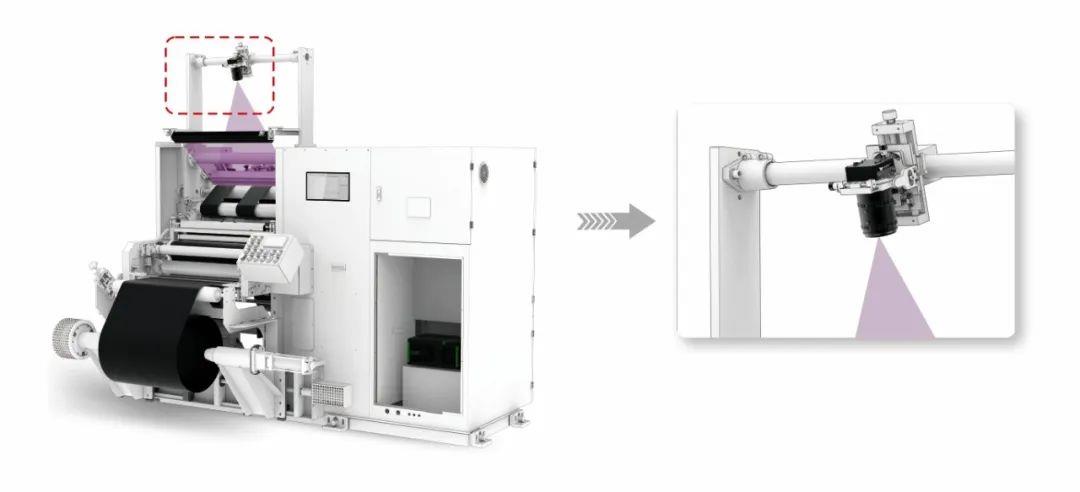

schematic diagram of OPT machine vision application in pole slitting machine

Therewith, OPT has launched a series of CXP area-array cameras which are suitable for lithium electrode sheet inspection. Combined with high angle and back lighting, the burr features in different directions are highlighted. This series of area-array cameras combine features of high bandwidth and high resolution, with a bandwidth speed of up to 20Gbps, a scanning speed that can cope with faster motion systems, and an inspection accuracy of up to 7μm.

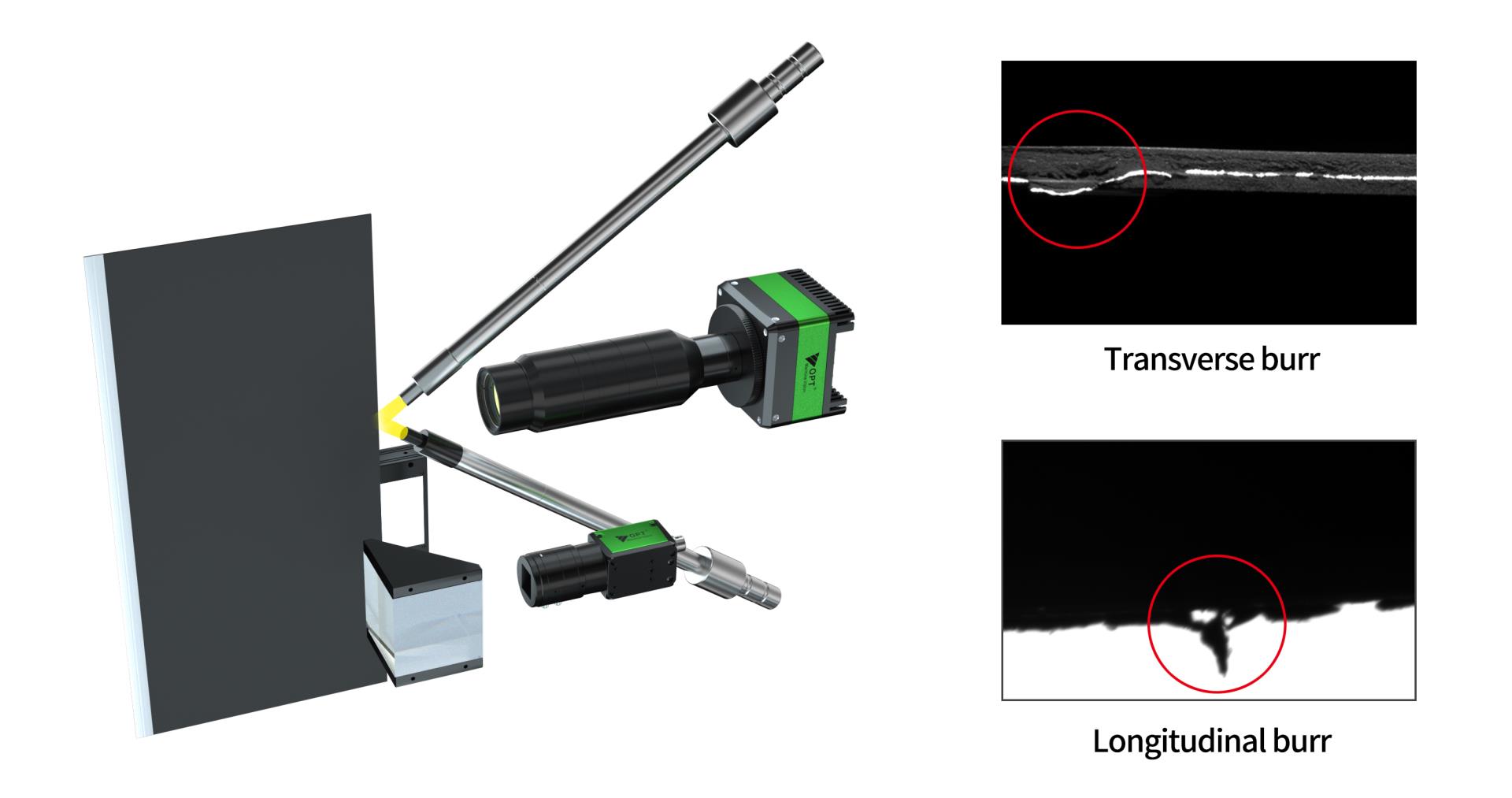

schematic diagram of OPT pole piece burr detection

During the implementation of the project, OPT accumulated a large number of pole piece burr sample data, and utilized deep learning software for training and labeling to generate an AI detection model, which can detect burrs of different sizes and forms quickly and accurately.

02 Polar Auricular Folding Detection

zero leakage throughout the process

Folding of the pole lugs has a serious impact on the quality of the battery and may even triggers potential safety hazards. Its visual inspection, as an important barrier to ensure the safety and performance of the battery, is one of the industry's difficulties.

Taking the winding of lugs as an example, OPT adopts high-speed line scan cameras and area-array cameras to inspect each piece of lugs on the core, with a scanning speed of 3m/s to ensure that the lugs are free of folding defects before winding.

schematic diagram of OPT machine vision application in pole ear winder

Meanwhile in the discharging segment, it is also necessary to detect the front and side of the lugs.OPT adopts a liquid lens to check whether the inner layer of the lugs is flipped and folded through multiple side imaging. The speed of focusing can reach the millisecond level.

Entering the electrode welding section, the visual inspection is even more stringent, requiring zero leakage inspection to prevent bare cores with defects such as flipped, broken and crumbs from flowing into the packaging section.

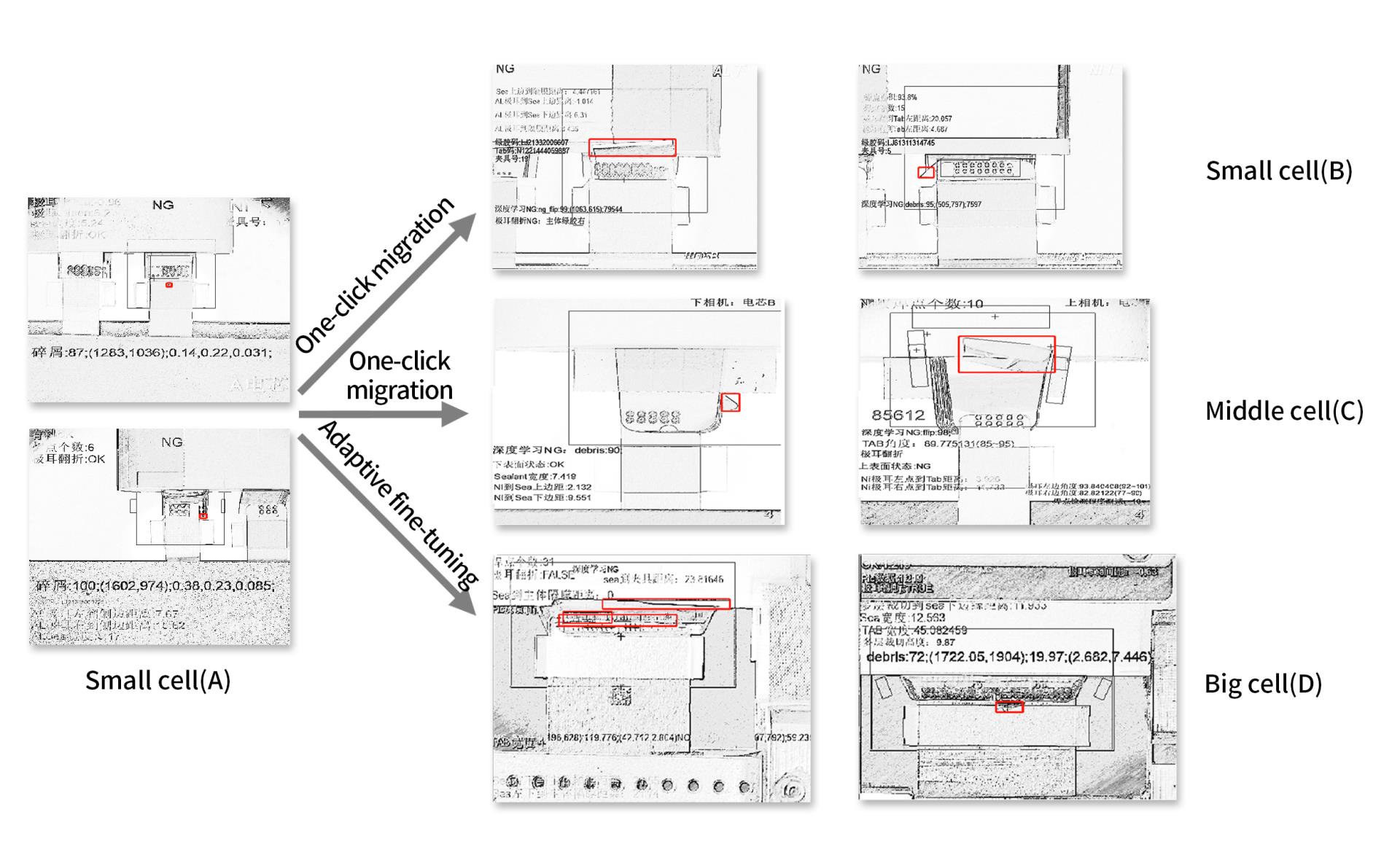

schematic diagram of OPT polar auricular fold detection

OPT makes full use of the combination of 2D vision algorithms and deep learning to carry out full inspection. By locating the main body of the core and the position of the pole lugs first, adding the ROI frame, using the deep learning target detection function to extract different defective morphology and color features next, then using the edge-finding and Blob analysis algorithms in the region of the two sides of the pole lugs to detect folding, the zero omission of the pole lugs detection can be achieved.

In the meantime, OPT has realized key technological innovations in small sample learning, migration learning,etc based on the lithium detection with deep learning, which not only solves the problem of over-reliance on a large number of defective sample data, but also dramatically shortens the training cycle. The product changeover detection with similar processes realizes one-key migration, and the project deployment is more efficient.

03 Six Side Inspection

more comprehensive, more efficient

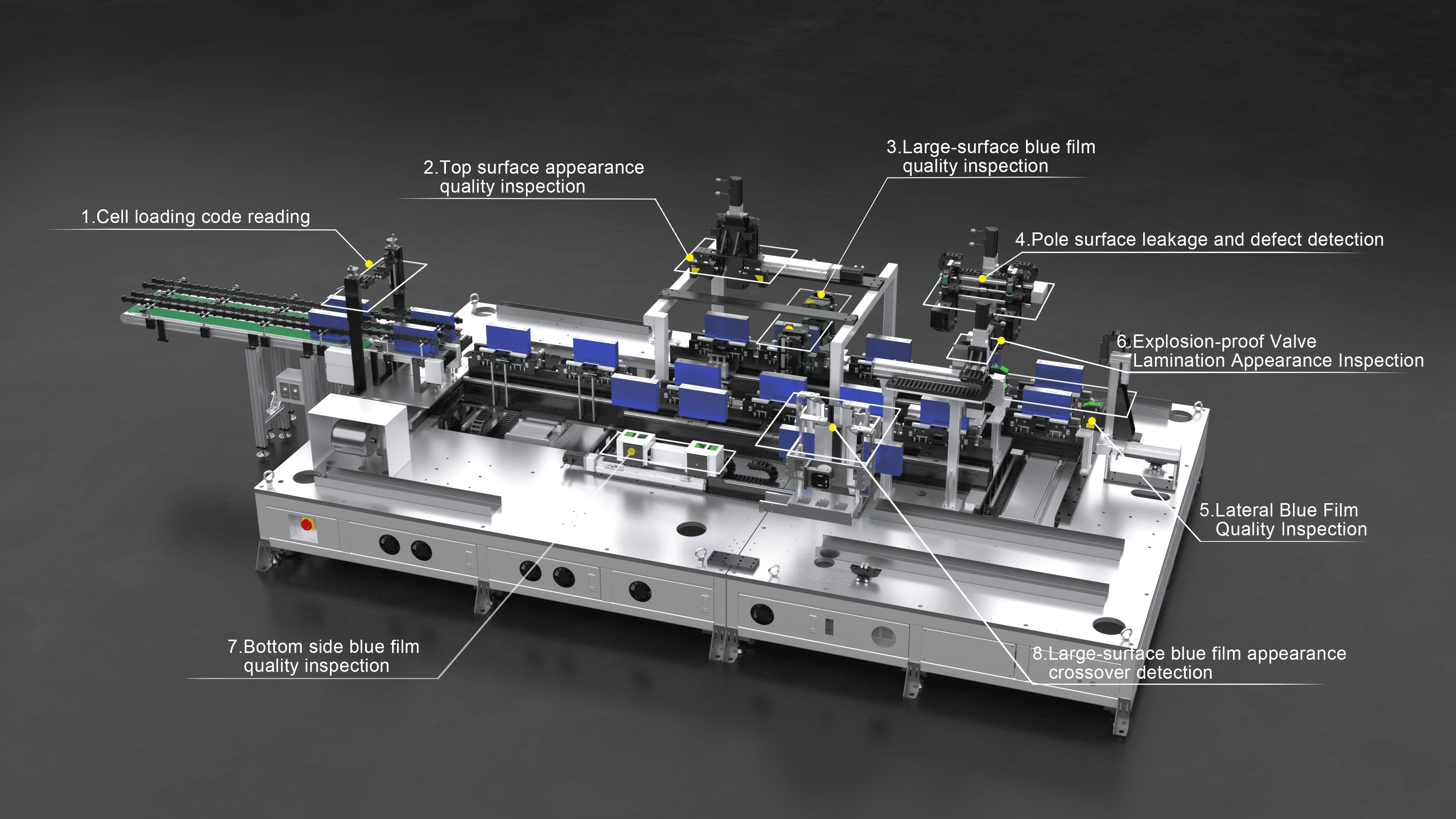

Coating blue film is an important process in the production of lithium batteries, which can play a role in insulating and protecting the battery cells. Affected by the material and thickness of the blue film, complex defects such as scratches and bubbles are likely to occur during the coating process. OPT has designed a vision program for six-side inspection of battery cells by deeply integrating 3D, 2D, frequency division and deep learning technologies. At present, the vision solution has been running stably in many project sites, and the inspection speed can reach 30PPM.

schematic diagram of six-side full inspection of film-coated battery cell

In order to avoid the influence of reflective materials such as blue film and metal top cover, OPT adopts 3D sensor with built-in high dynamic algorithm, which automatically tunes the laser power and gain, so that the imaging of all kinds of materials is stable and clear. Moreover, combined with the 3D surface defects detection algorithm of Smart3 vision software, the use of datum fitting and surface correction can accurately locate the defects and extract the characteristics of the information, such as the top insulating board's damage, warping and indentation; the surface of the pole columns' stains and overflow of adhesive, as well as the craters and convexity of the blue film.

For the detection of electrolyte corrosion in the top cover of the battery core, OPT adopts low angle lighting method to stably detect electrolyte crystals with a diameter larger than 2mm. At the same time, it utilizes the diffuse reflection characteristics of the dom light to penetrate the PP film of the anti-explosion valve and detect the foreign matter and electrolyte under the PP film accurately.

In the six-side inspection solution of the electric core, OPT also combines the split-frequency technology, which makes the light source strobe rapidly, and obtains several different optical imaging effects in one scanning. Supplemented by the deep learning algorithm function, it can judge the defects accurately and avoid leakage inspection and misjudgment.

EN

EN CN

CN JP

JP