OPT one-click measurement sensor-SmartFlash

OPT one-click measurement sensor-SmartFlash integrates AI technologies of machine vision, such as edge extraction, automatic matching, automatic focusing, automatic learning and image synthesis. It involves four guarantees for high precision (micron level), with the double telecentric optical path, multi-angle lighting system, high-precision motion platform, and subpixel edge extraction algorithm for image processing.

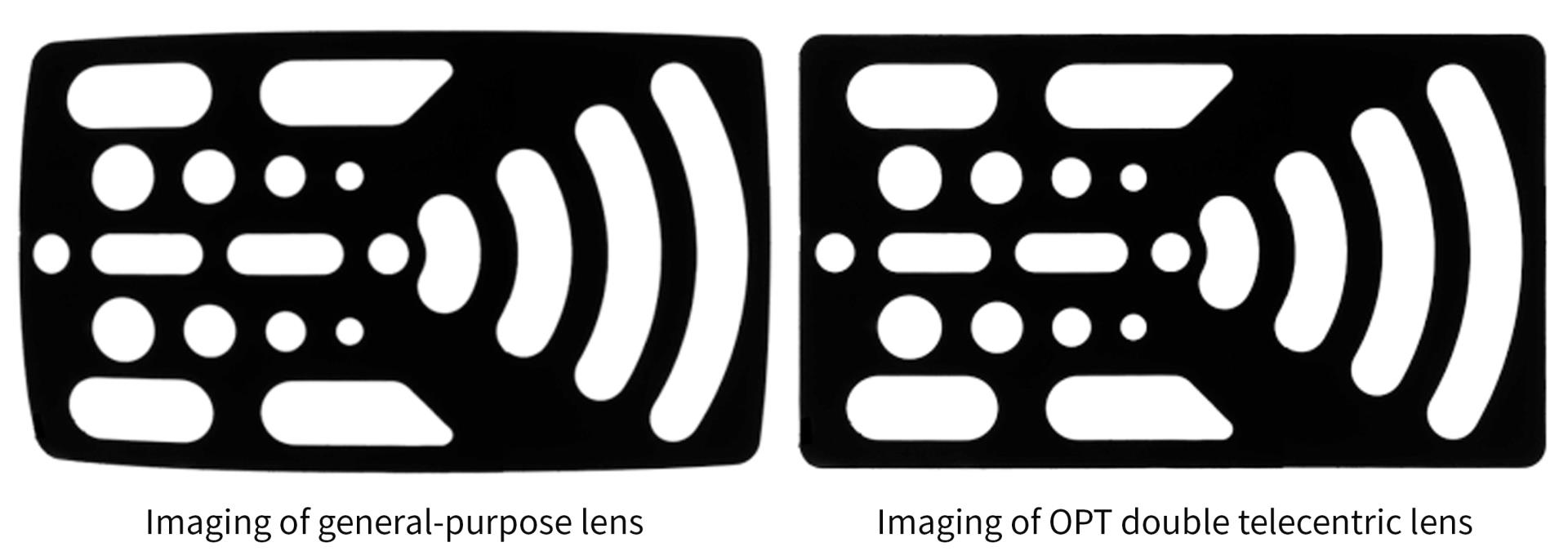

Double telecentric structure for no perspective distortion

The precision of dimensional measurement is critical for product quality control. The conventional measurement mode has the disadvantages of complicated operation and unclear images, which probably leads to measurement errors.

OPT one-click measurement sensor-SmartFlash adopts the double telocentric structure, which has the advantages of object telocentric lens and image telocentric lens. It features large depth of field, nearly zero distortion and the like, thus giving full play to the parallelism of light, eliminating the perspective distortion of object telocentric lens, avoiding illumination attenuation and improving the measurement accuracy.

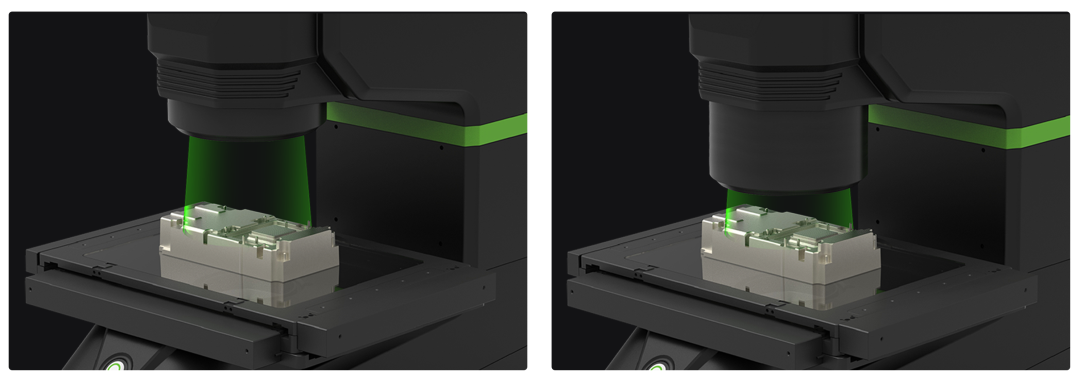

Double telecentric lens module

For some targets with uneven surfaces, the one-click measurement sensor SmartFlash has the function of automatic focusing based on the measurement position, to avoid focusing errors of operators and solve the problem of focusing at a time. Even the targets with height differences can be measured accurately.

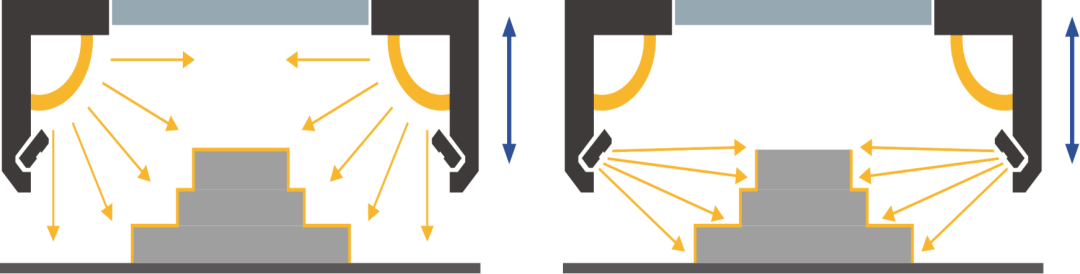

Multi-angle lighting system for clearer edge profile

In terms of dimensional measurement, in order to avoid the impact of reflective or low-reflectivity materials and improve the clarity and sharpness of the edge profiles of objects, OPT one-click measurement sensor-SmartFlash adopts a multi-angle lighting system, in which diffused light from eight channels is combined with telecentric parallel light into a lighting unit to provide light at different angles, eliminate edge blurring arising from light diffusion and accurately measure objects at various reflectivity levels. It is stably suitable for objects of different materials and colors.

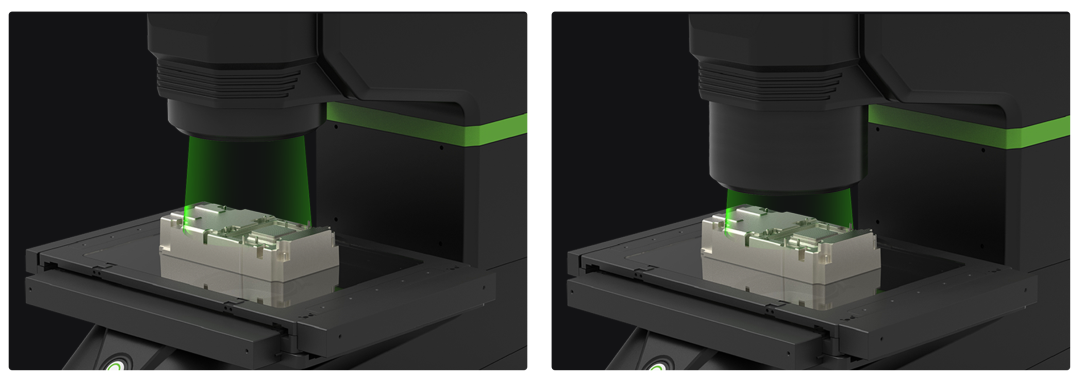

Automatic adjustment of light source height

The one-click measurement sensor-SmartFlash is also equipped with a four-axis motion control system, which can automatically adjust the light source to the best height through the software algorithm, so that mosaic images have a light and shade contrast and image edge profiles are clear. Even if a target is far away from the light source, lighting is uniform within a large range to take clearer images.

Schematic diagram of multi-angle lighting

When used to measure the dimensions of a dark radiator, the one-click measurement sensor-SmartFlash is able to automatically adjust the light source based on objects’ surface features. When the light source is at a low angle, objects’ surface features irradiated from the lateral side can be presented more intuitively, which is helpful to improve the accuracy of peripheral profile detection.

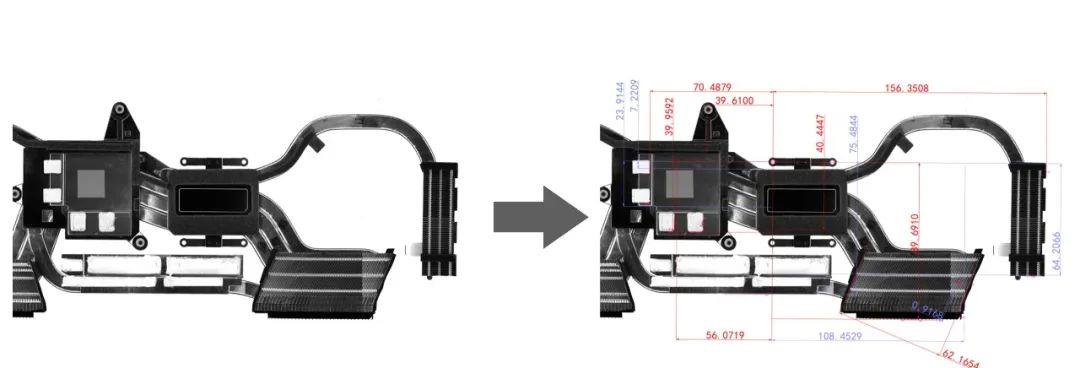

High-precision motion platform for higher image mosaic accuracy

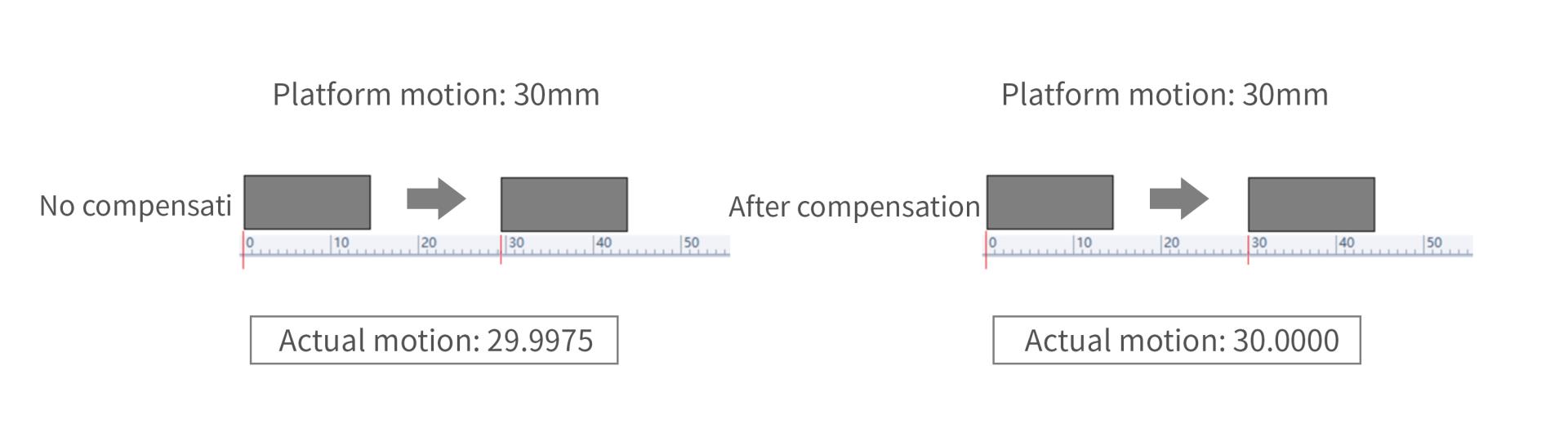

For the accurate measurement of large-size products, the one-click measurement sensor-SmartFlash is equipped with a high-precision motion platform driven by a linear motor and a grating ruler (resolution: 0.1μm) for closed-loop control, thereby increasing the running speed while ensuring the positioning accuracy.

Compared with the conventional screw drive system, the one-click measurement sensor-SmartFlash has a more compact platform, subject to more stable linear motion instead of rotational motion but without additional devices. Therefore, the measurement accuracy is not affected by the round-trip platform and lead screw. This is conducive to image mosaic applications due to zero reverse clearance, low repetition accuracy and no error accumulation.

The one-click measurement sensor-SmartFlash is also equipped with professional measuring tools to adjust hardware accuracy and calibration compensation algorithm for error compensation and micron-level motion accuracy.

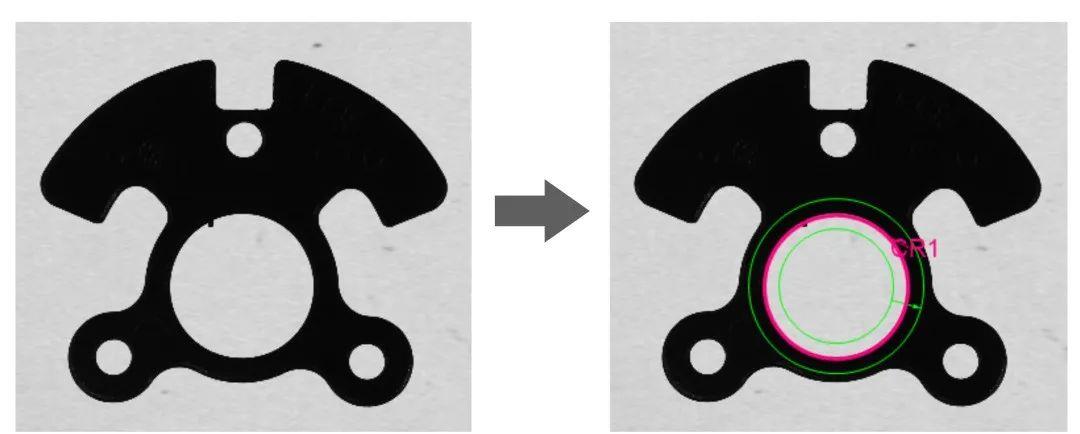

Subpixel edge extraction algorithm for high-precision measurement

OPT one-click measurement sensor-SmartFlash adopts the subpixel edge extraction algorithm, in which the least square method is applied. CAD drawings can be imported for high-precision measurement without programming.

Dimensional measurement of steel parts has high requirements for precision control. In addition, a number of parts should be measured. In the software algorithm of the one-click measurement sensor-SmartFlash, a single pixel is divided into 100 subpixels, edge features are fitted by the least square method, and edge burrs, black shadows and white bright edges are eliminated automatically by the burr filtering algorithm, thus greatly improving the measurement accuracy.

Edge burr filtering

Products with multiple Z-axis parts to be measured can also be measured at a time by the one-click measurement sensor -SmartFlash. Focus areas can be extracted and spliced in the focus splicing mode to finally obtain clear images.

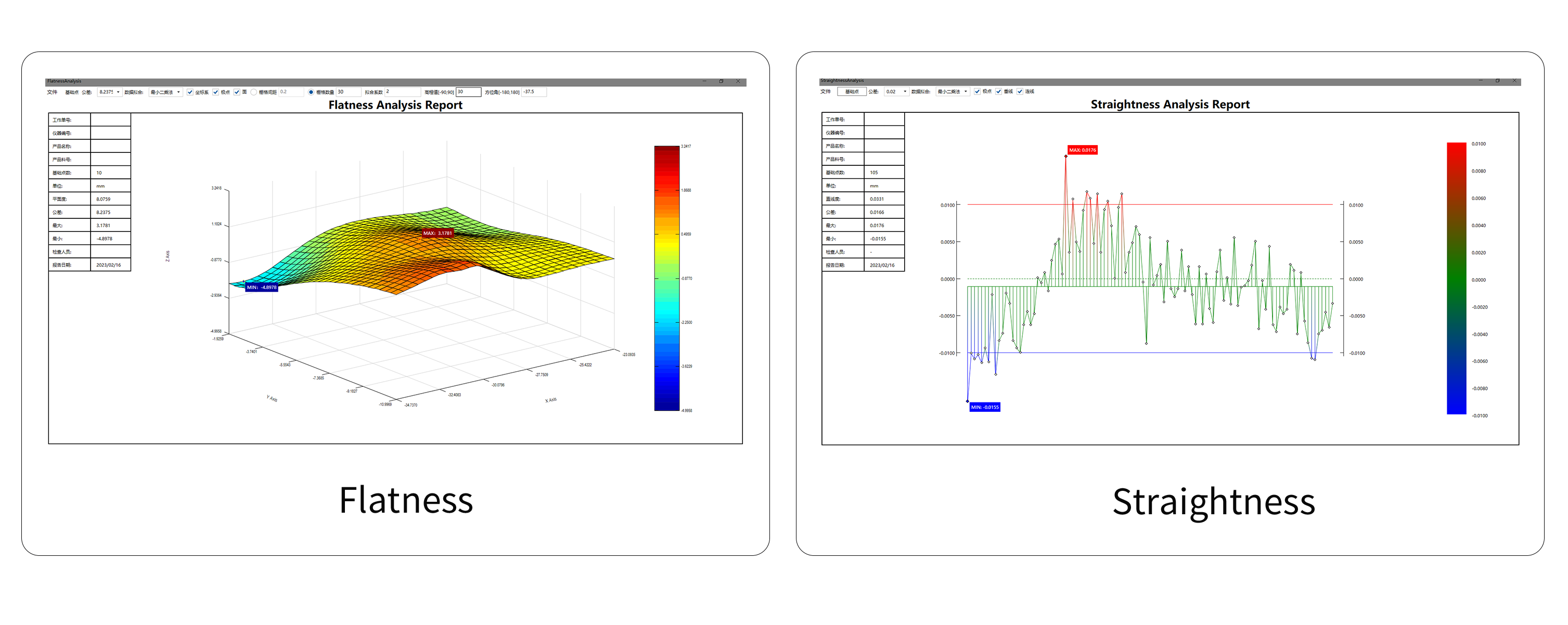

In addition, the one-click measurement sensor-SmartFlash has the functions of profile analysis and aluminum profile measurement, and supports the output of custom detection reports. It has three visual analysis tools for flatness, roundness and straightness. Through the statistical calculation of measured data, Cpk values, histograms, X-S charts, X-R charts and IX-MR charts can be generated. SmartFlash is widely applied in dimensional measurement of metals, plastics and other materials.

EN

EN CN

CN JP

JP