Application of Smart Code Reader in Industries Including Lithium Battery and 3C Manufacturing

Built-in AI Intelligent Control System Helps to Read Code Efficiently and Accurately

Industrial code reading technology has been widely used in product backtracking and tracking. Code reading efficiency and accuracy are important criteria for measuring the performance of code readers.

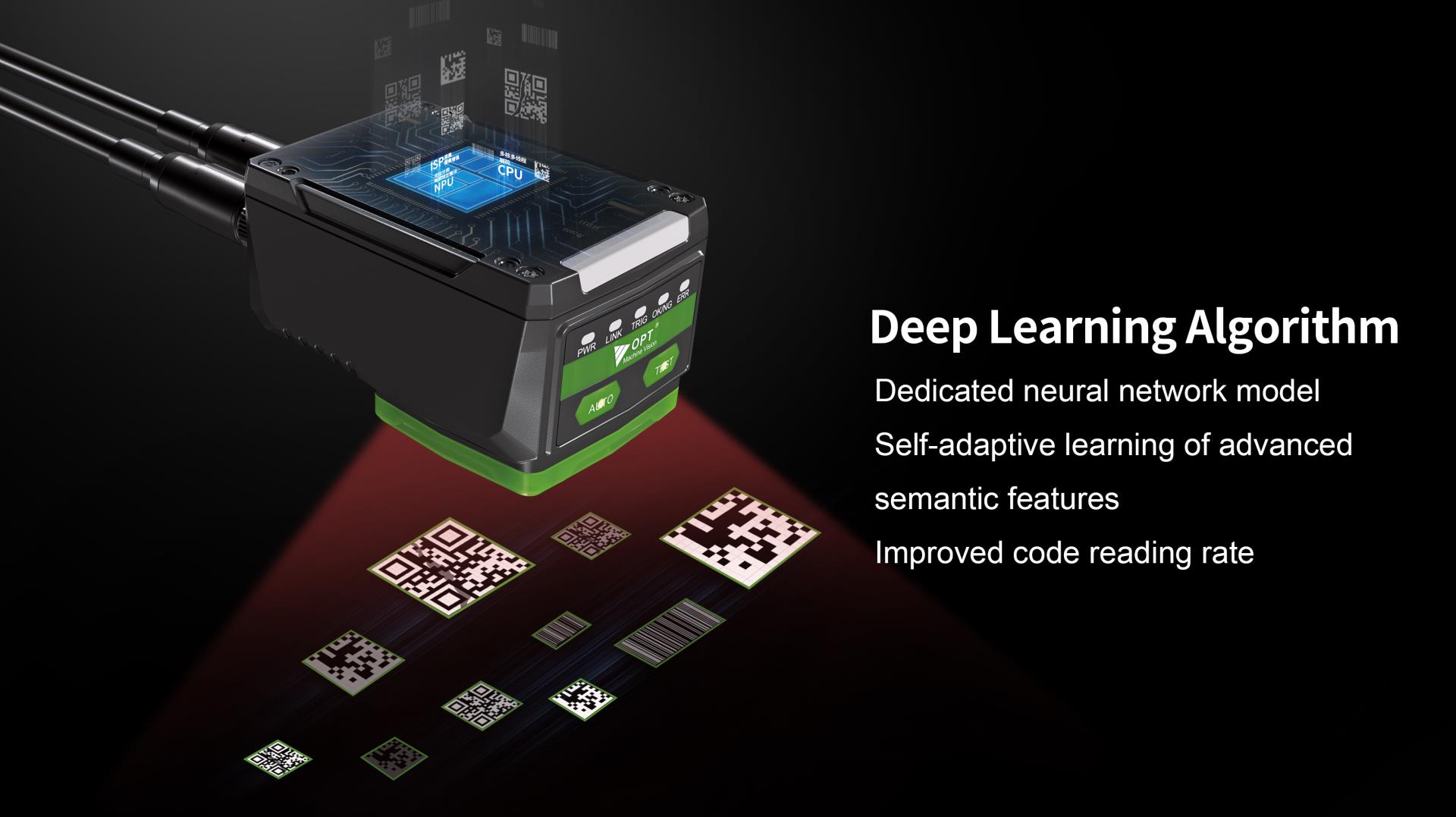

The OPT Smart Code Readers have resolution of 0.4MP to 20MP, integrates the AI intelligent control system, adopts multi-core heterogeneous parallel computing and makes CPU, NPU and ISP parallel through a 3-stage pipeline software architecture. There is no waiting time required for the processes from capturing the barcodes, to image pre-processing, and finally decoding. The built-in CPU of the smart code readers has the function of multi-core and multithreading data processing. Unlike other single-threaded code readers, the reading time is shorter and the decoding is more efficient for smart code readers.

The AI intelligent control system of the smart code readers has built-in Deep Learning algorithm and distortion correction algorithm. The Deep Learning algorithm can self-adaptively learn the semantic features, automatically distinguish barcode components, characters and abnormalities, and is not affected by the barcodes due to damage, blurry, poor printing quality, etc. while obtaining the barcode information accurately. The distortion correction algorithm can automatically correct the distorted barcodes at curved surface of cylindrical batteries and remain readable.

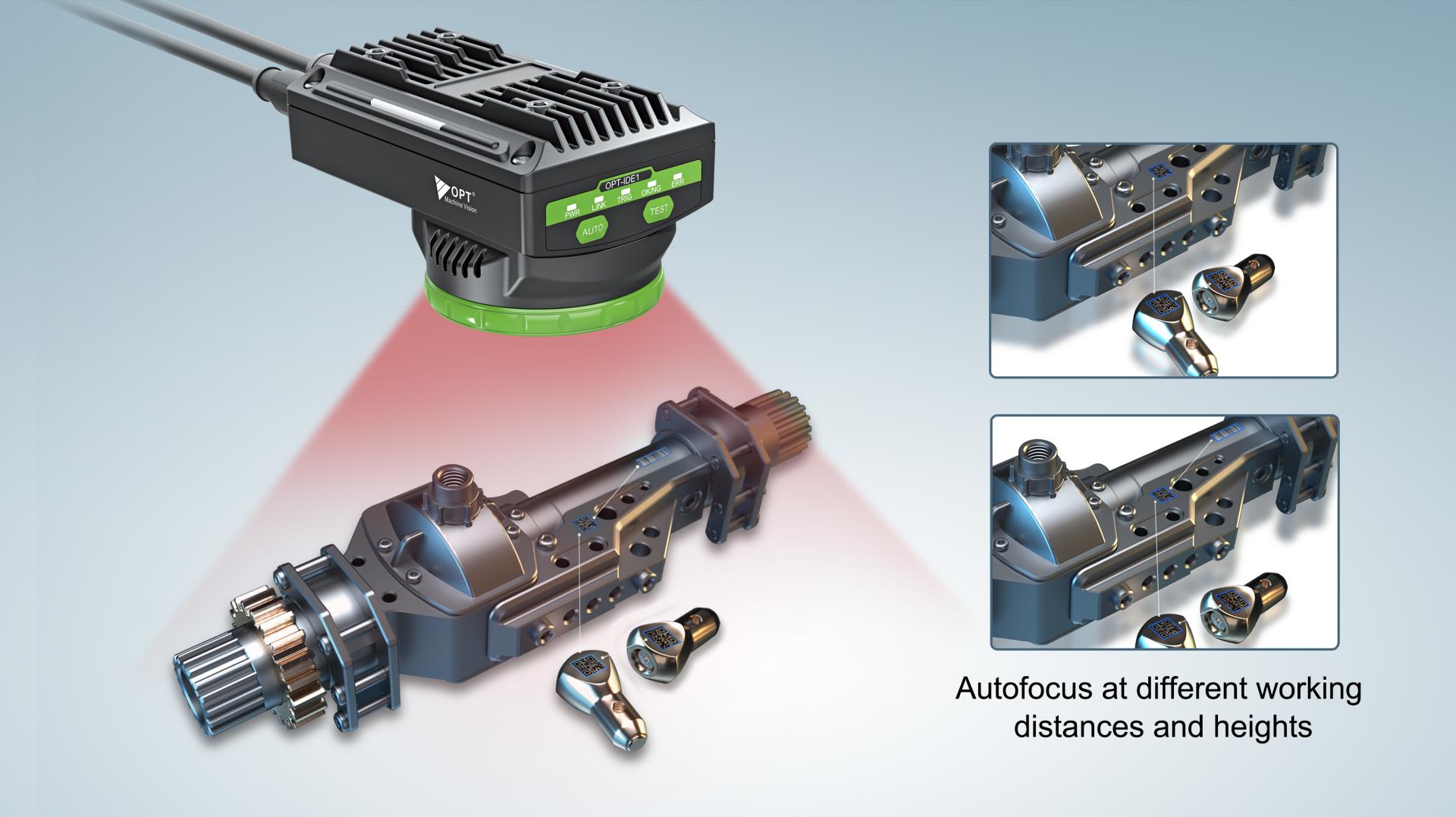

Compatible with Liquid Lens and Suitable for High-Speed Dynamic Code Reading

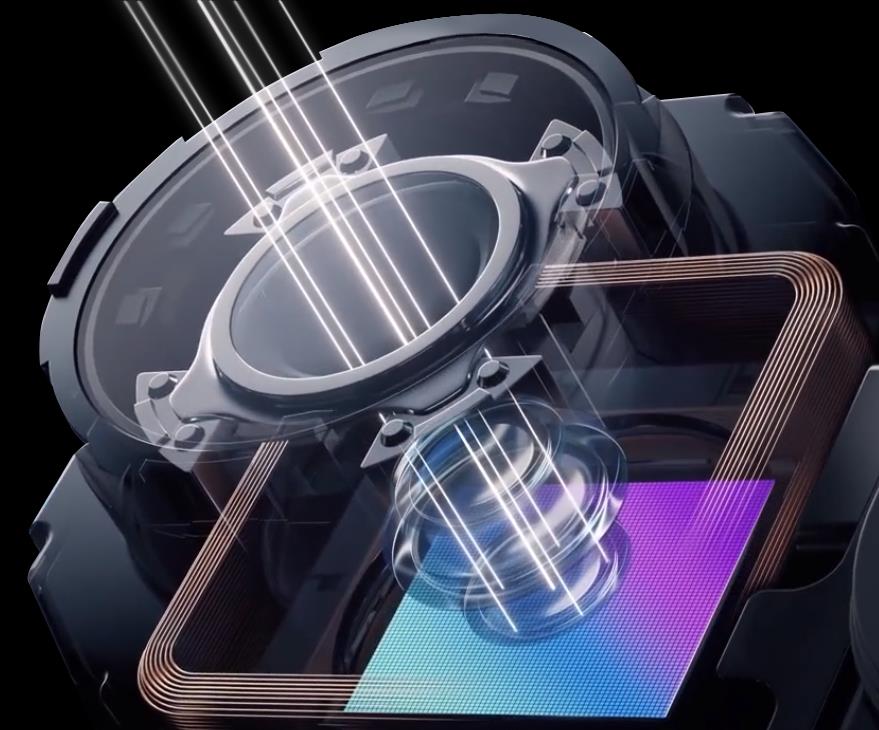

All smart code readers support automatic tuning with one-button, built-in focusing and decoding algorithm. Users can freely choose mechanical focusing or liquid lens focusing technology to achieve automatic focusing and quickly get a clear imaging.

OPT Liquid Lens Focusing Technology

The liquid lens technology is designed according to the principle of bionics. The curvature is changed by current-driven pressure to achieve fast focusing with response speed in milliseconds. The image quality acquired by the lens is not affected by distance. The image obtained is clear and optimum for subsequent decoding.

Note: Some models are equipped with liquid lenses

Meet the Demand of Code Reading in Industries of Lithium Battery and 3C

In order to better cope with the factors such as complex environment of the code reading, impact of material reflection and low contrast, OPT Smart Code Readers are using multi-channel uniform light illumination system. Four light sources can be independently controllable, with the color selections of white, red and blue lights. Polarizing filter design helps to eliminate the impact of reflection, ensuring a stable reading of barcode of any material reflectivity.

OPT’s main businesses cover hundreds of processes in more than 30 industries such as lithium batteries, 3C, semiconductors, photovoltaics, etc. Nevertheless, the OPT Smart Code Readers can meet the code reading requirements of different industries.

For example, the application of OPT Smart Code Readers covers the middle and later stages of lithium battery manufacturing processes including winding, cold-pressing, jelly roll, ultrasonic welding, electrolyte filling, welding of sealing cap, packaging, unloading, etc.

EN

EN CN

CN JP

JP