Application of Smart3 Machine Vision Software

OPT has held a webinar regarding machine vision technology on 21 October. The webinar was mainly discussing about the Smart3 software and went deeper into the application and usage of visual programming and user interface customization of this machine vision software. The topic was shared by Mr. He Shilong, the technical director of OPT.

OPT Smart3 software improves continuously by learning through the application of machine vision software in multiple industries. It integrates the algorithms such as 2D, 3D, Deep Learning, etc. with comprehensive functions that covers the positioning in assembly line, product measurement, quality inspection, barcode reading, etc. In addition, it supports various industrial cameras and GeniCam standard protocols such as high-resolution line scan cameras or area scan cameras to meet the needs of different machine vision applications.

Smart3 Machine Vision Software

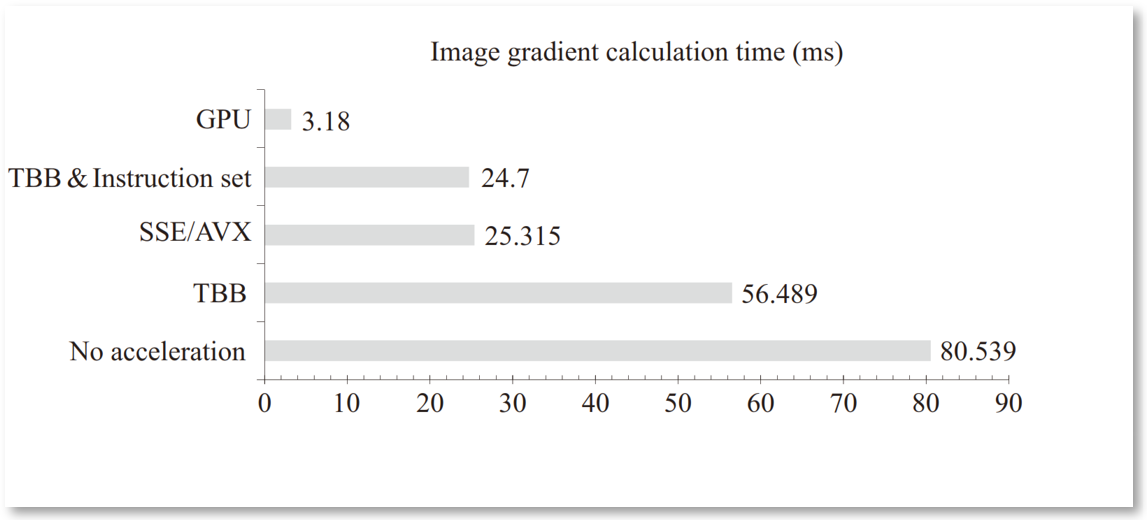

Machine vision software acts as a “brain” of the machines. As the manufacturing industry increases the production rate, correspondingly higher requirements to the speed at which the “brain” could process the images and analyze them.

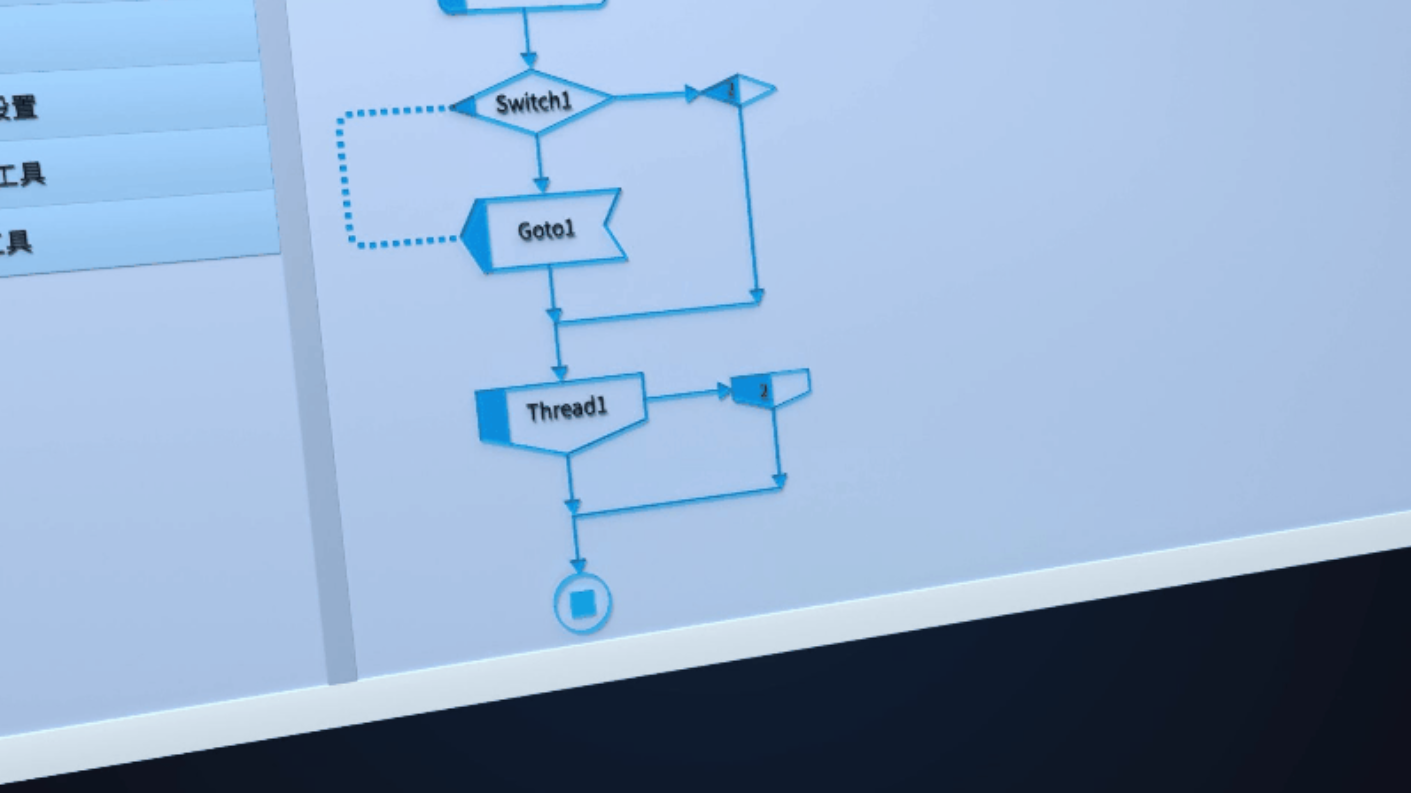

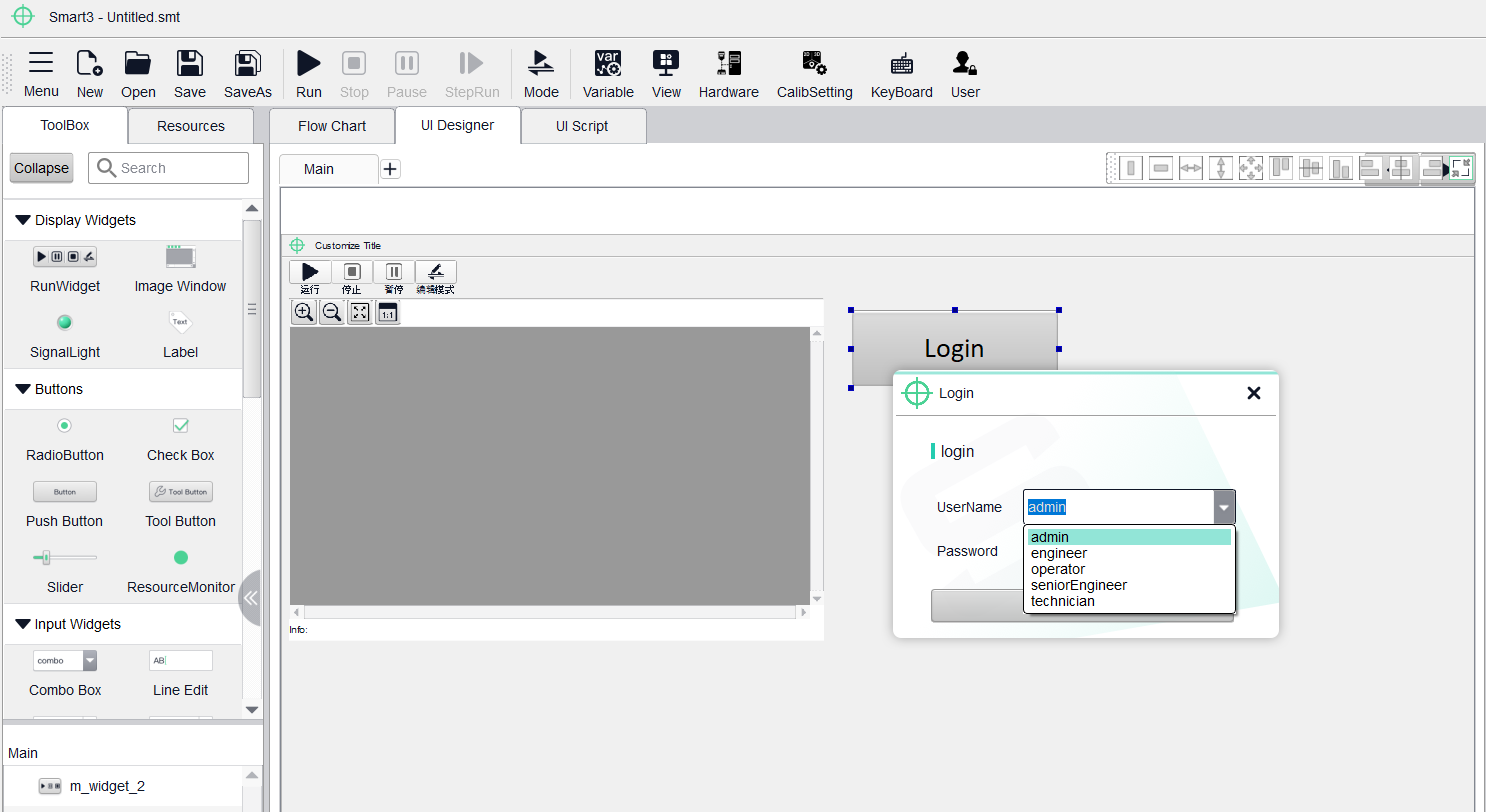

Smart3 is a more efficient machine vision software. One of the most prominent advantages is that it adopts visual programming design instead of the traditional method of using complicated codes and abstract process flow. The flow chart can be easily deployed by adding Operator blocks, Goto blocks, Thread blocks and Switch blocks, which greatly shortens the project development cycle and quickly respond to user needs.

Added Goto Block, Thread Block and Switch Block

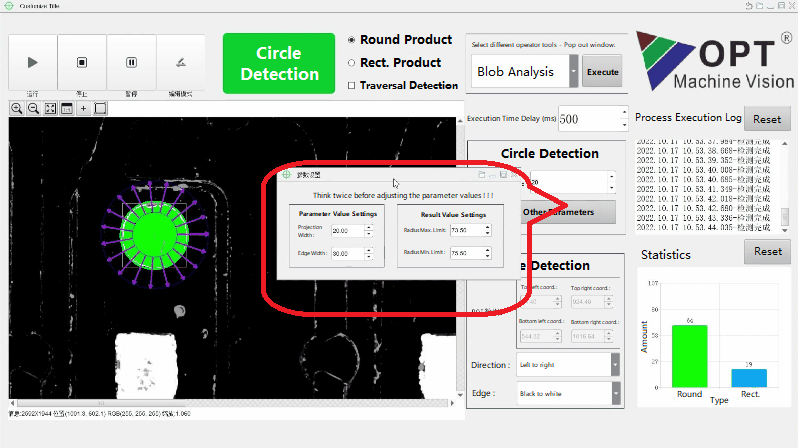

One of the block functions in Smart3, Condition Switch, can distinguish different work instructions and execute the corresponding inspection process. When using the Thread Block, it can execute multiples tasks at the same time to meet different inspection requirements.

In addition, Smart3 also supports sub-flow design, which can be triggered by events and run independently from the main flow process, providing a more intuitive and concise flow chart for multi-station inspections with high readability of the program. At the same time, the sub-flow supports import and copy/paste blocks, which fasten the verification of cycle time during process development stage and ease the users with better inspection solutions.

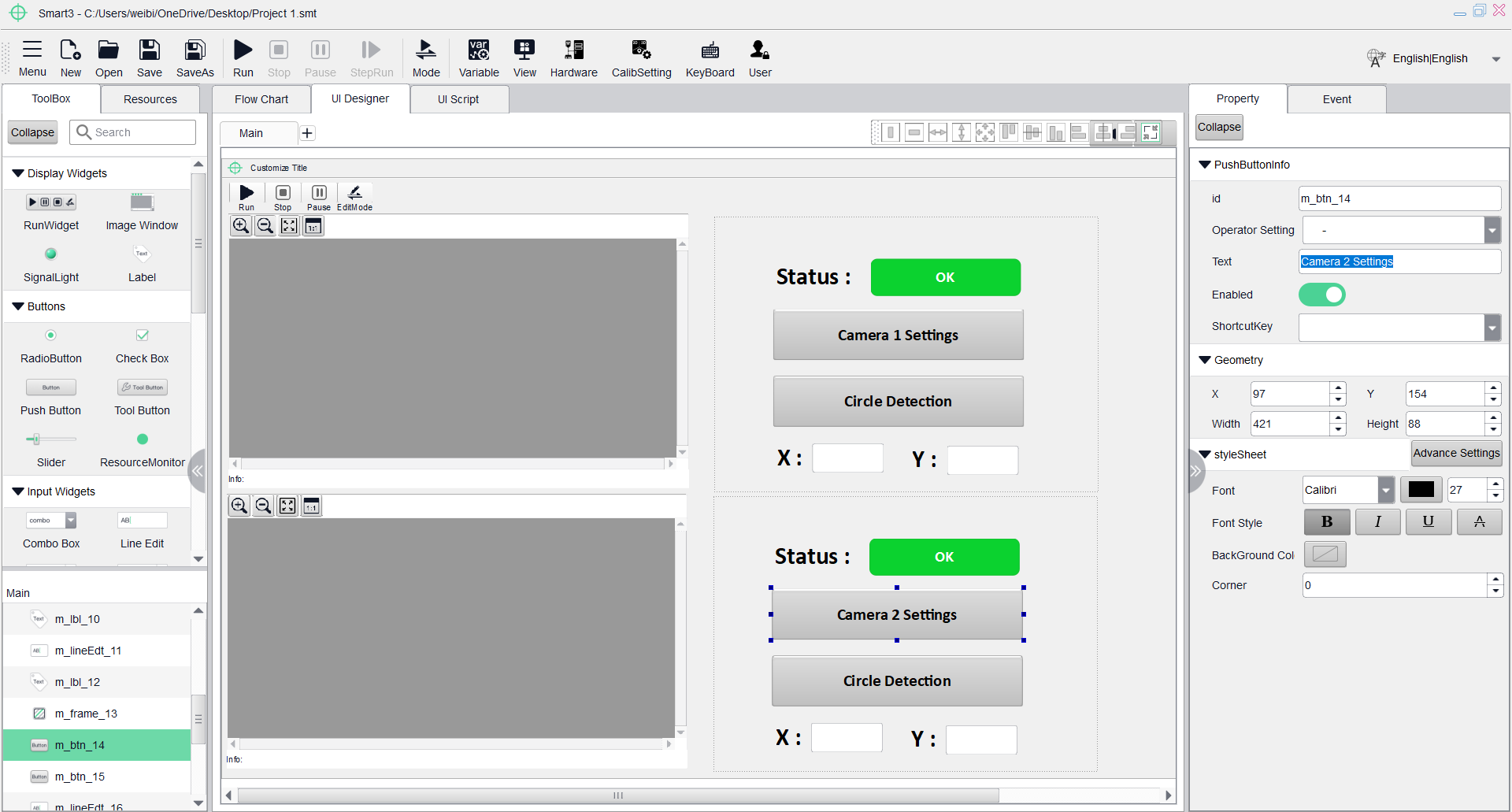

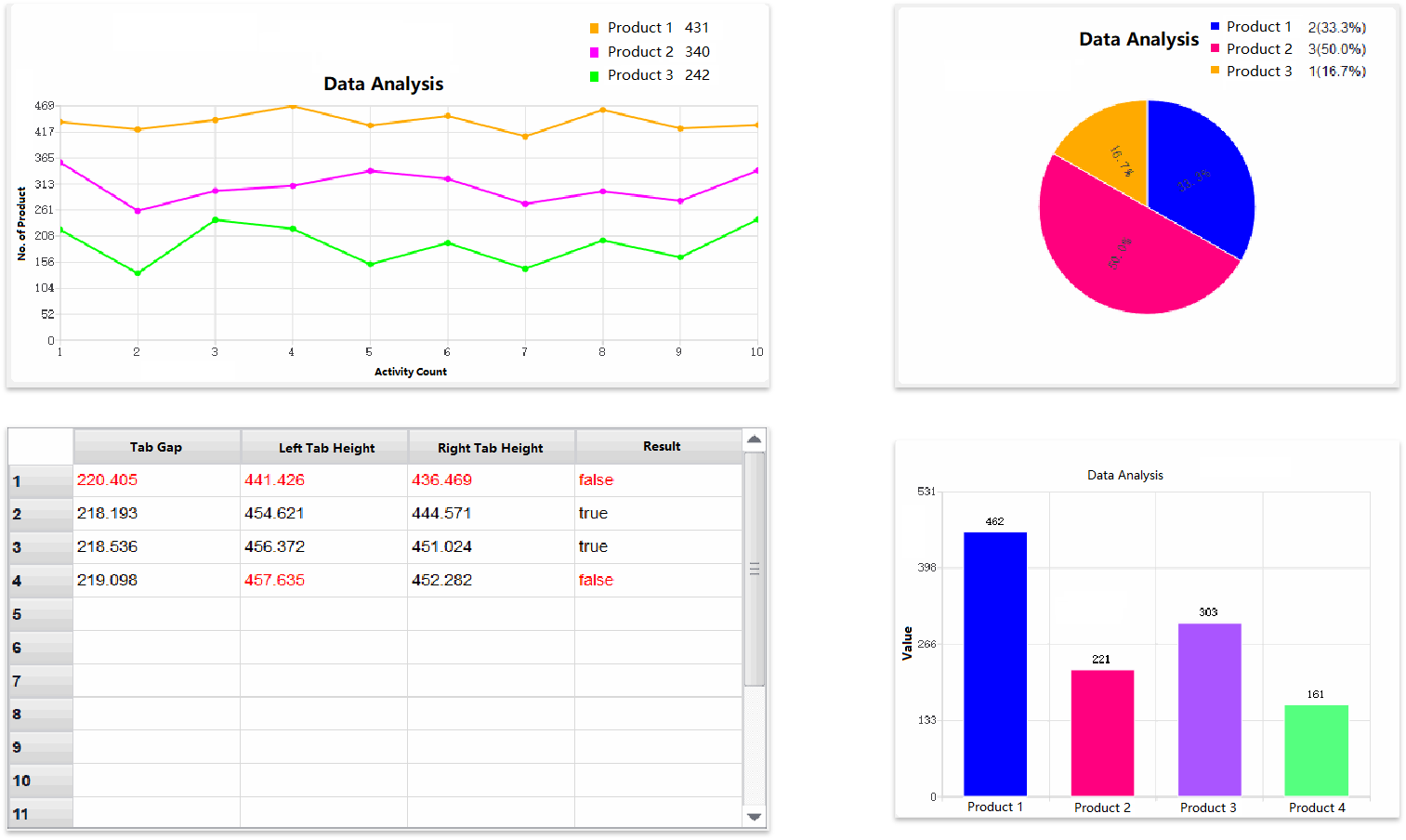

UI Customization, A User-Centered Design

In the process of customizing the interface, a variety of widgets and buttons with different functions are available. The rich interface elements can be easily dragged and dropped freely, which are easy and convenient for users to quickly complete the customization of the running interface. The inspection results can be clear at a glance and users can obtain all the required inspection information at ease.

Smart3 software uses Cpk and can intuitively display data such as product qualification rate and production status. Smart3 can also set the access permissions and configure different user roles to ensure the security of the program.

EN

EN CN

CN JP

JP