Applications of the OPT High-Speed Line Scan Cameras for Machine Vision Inspection

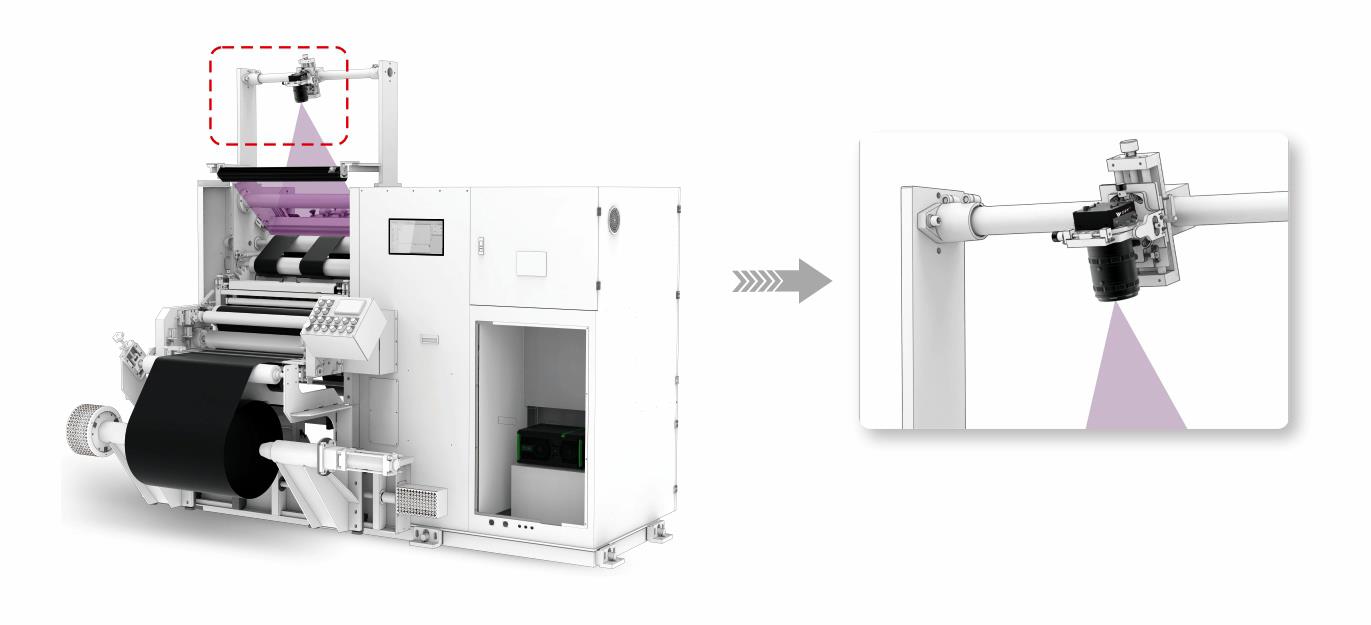

To meet the requirements of fast and accurate machine vision inspection of lithium batteries, OPT has combined the high-resolution line scan camera lenses with line scan cameras of ultra-fast line frequency. This combination offers advantages such as a long transmission distance and the possibilities of edge computing, which better meets the actual needs of users.

Ultra-High Lateral Resolution and Multiple Correction Algorithms

Initial and mid-level processes in lithium battery manufacturing include many large format and high speed inspection applications. Examples include coating, cutting, and winding processes that require ever increasing resolution and field of view for machine vision. The line scan camera launched by OPT has a maximum resolution of up to 16k, very large pixels, and thus excellent light-sensitive performance, high signal-to-noise ratio (SNR) and sharper captured images.

OPT Line Scan Cameras

Based on this, the OPT line scan camera also integrates various correction algorithms, such as Fixed Pattern Noise (FPN) and Photo Response Non-Uniformity (PRNU). It supports ROI, camera gain and specular reflection functions that ensure uniform image brightness and no vertical lines within the field of view, even when imaging objects with low reflectance. Of course, high quality images will also be captured for subsequent machine vision software to identify and analyze defect features.

With the advancement of intelligent lithium battery manufacturing, the accuracy of machine vision inspection is increasing day by day. Besides clear image acquisition, the machine vision system additionally places high demands on camera bandwidth and transmission range.

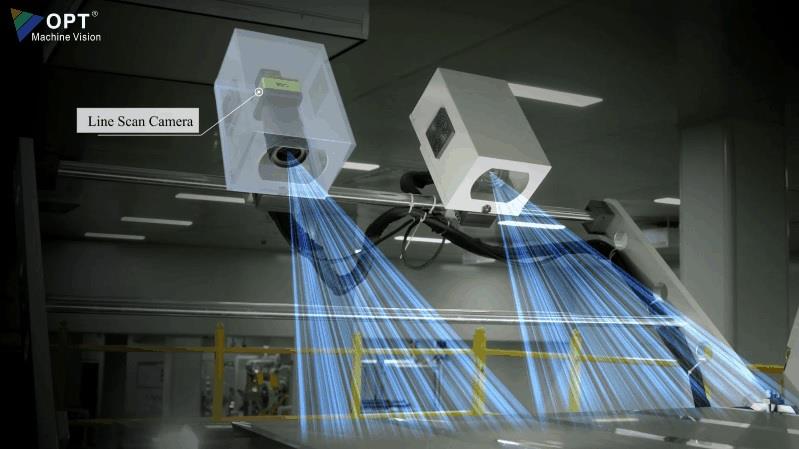

The OPT line scan camera is equipped with an ultra-high line rate line sensor, a 10 Gigabit Ethernet port, and a lossless compressed image design. This significantly improves the camera's acquisition speed and quality. The OPT XG Series 8k line scan camera, for example, features an ultra-high line frequency of 140 kHz and supports a transmission bandwidth of 1250 Mbps and ultra-long distance transmission of 100 meters.

Compared to conventional CameraLink line scan cameras, the XG series line scan cameras do not require frame grabbers to be configured. In addition, the line frequency and bandwidth are increased by about 50%. The transmission distance is also increased by 10 times, which is particularly suitable for target inspection, which has certain requirements for the speed of the production line.

In lithium battery coating, for example, the current production line speed can reach 120 meters per minute, and it will become even faster in the future. Currently, OPT can achieve an inspection speed of 200 meters per minute with six line scan cameras, which are not affected by long transmission distances and signal attenuation.

When inspecting large-format objects moving at high speed, the camera's bandwidth and transmission range, as well as the camera's processing power, pose a major challenge to the overall machine vision system.

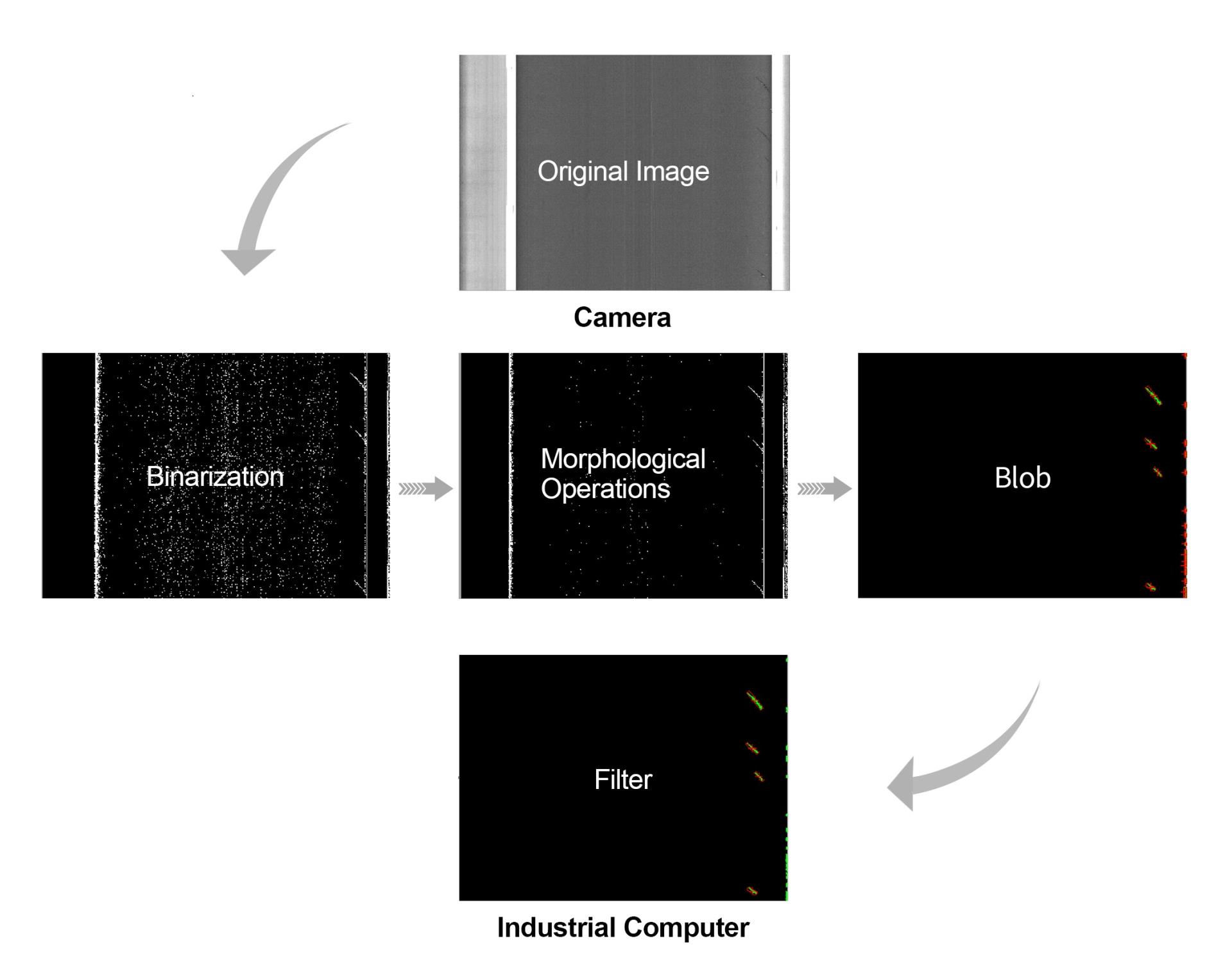

The OPT line scan cameras support hardware acceleration of algorithms that can take full advantage of FGPA's parallel computing technology, embed image preprocessing algorithms, and perform functions such as binarization, morphology, and blob analysis in real time.

Then, the processing results are transferred to the host computer along with the images. The host computer only needs to compile the subsequent results, which significantly reduces the CPU load on the industrial computer and best meets the testing requirements of high-speed lithium battery production.

Schematic Representation of the Real-Time Image Processing of an OPT Line Scan Camera

EN

EN CN

CN JP

JP