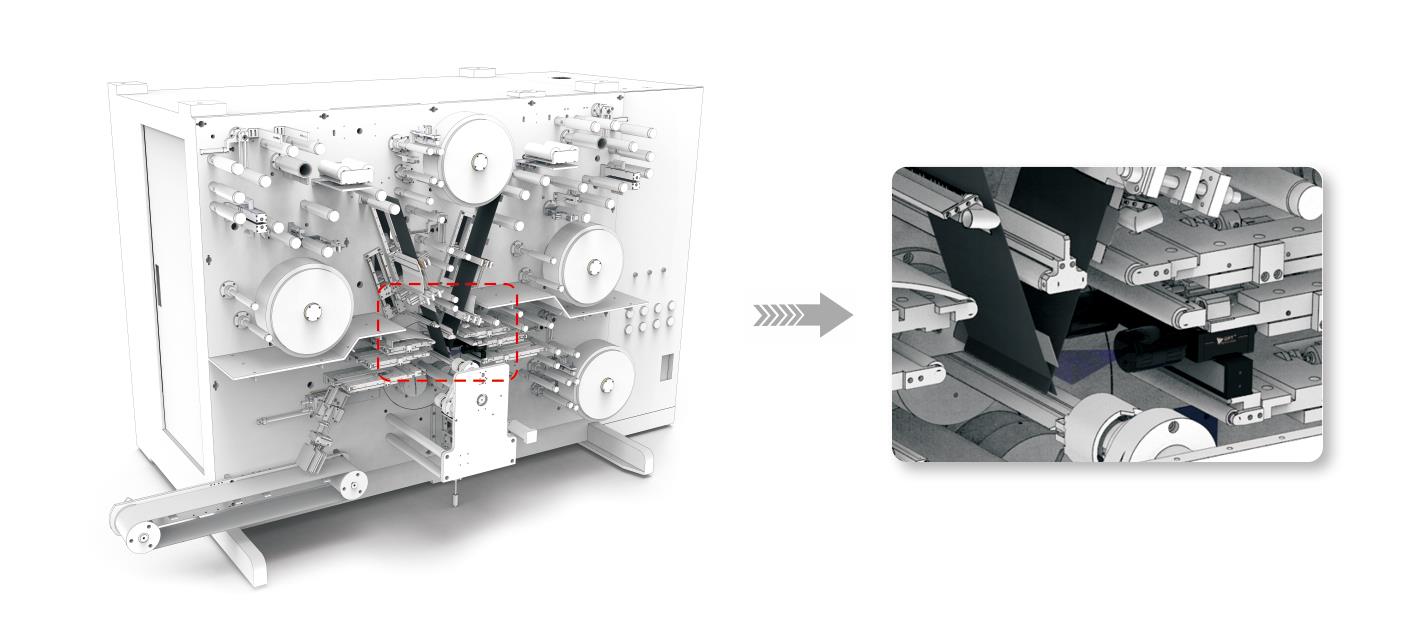

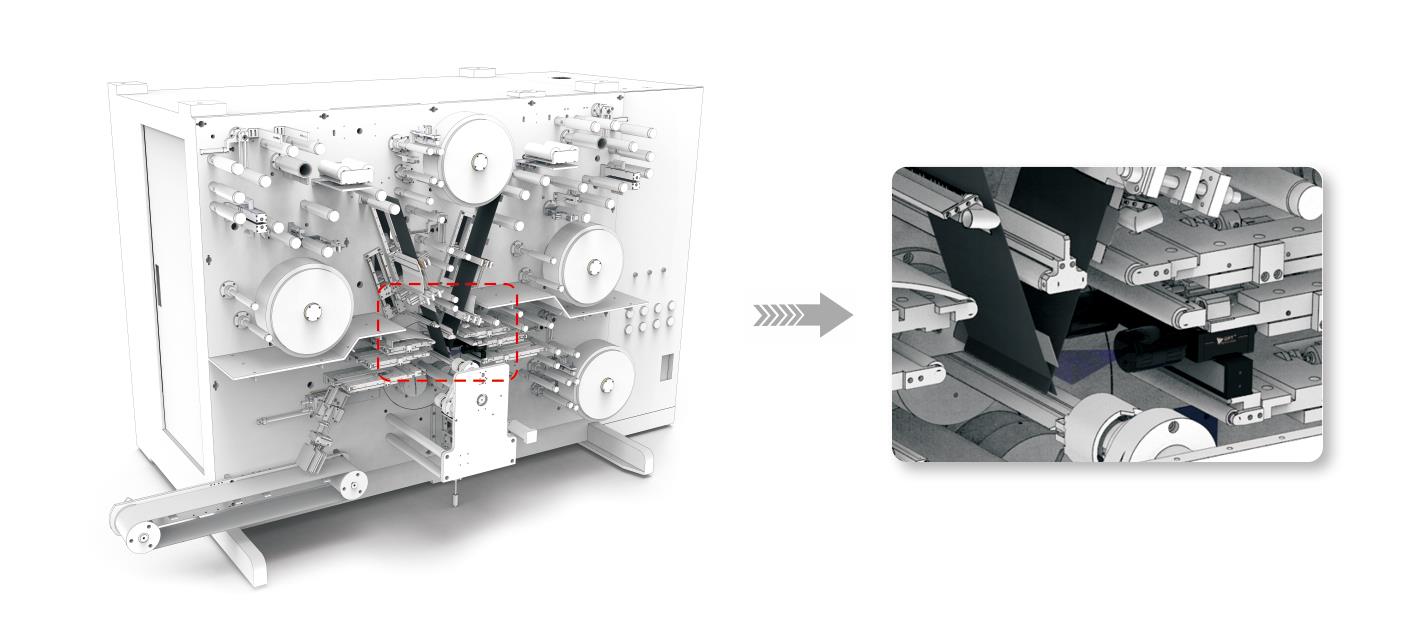

OPT Inspection of Lithium Batteries for Tab Defects

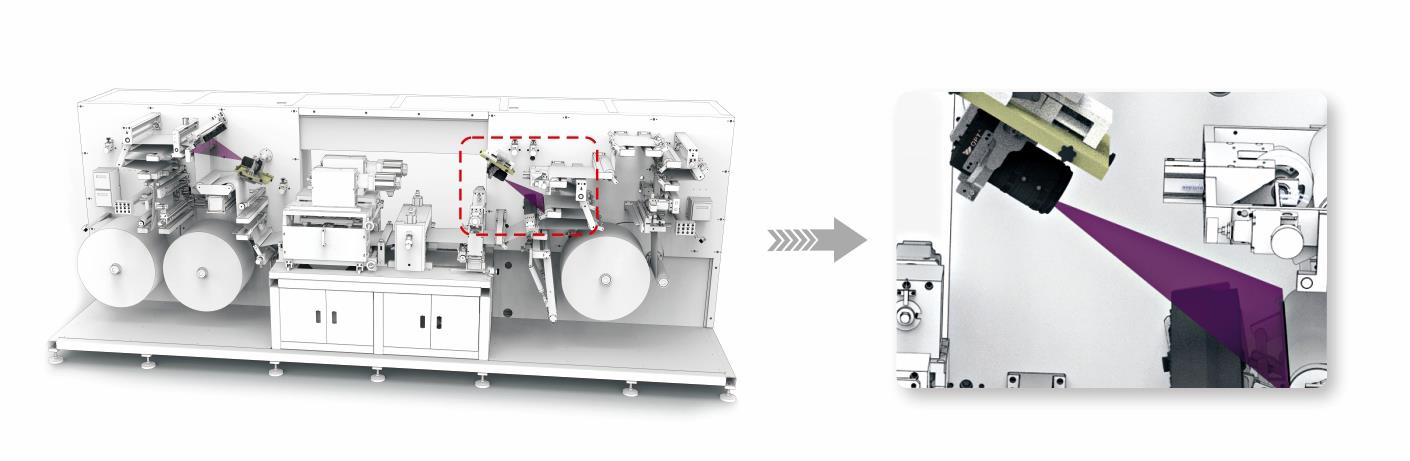

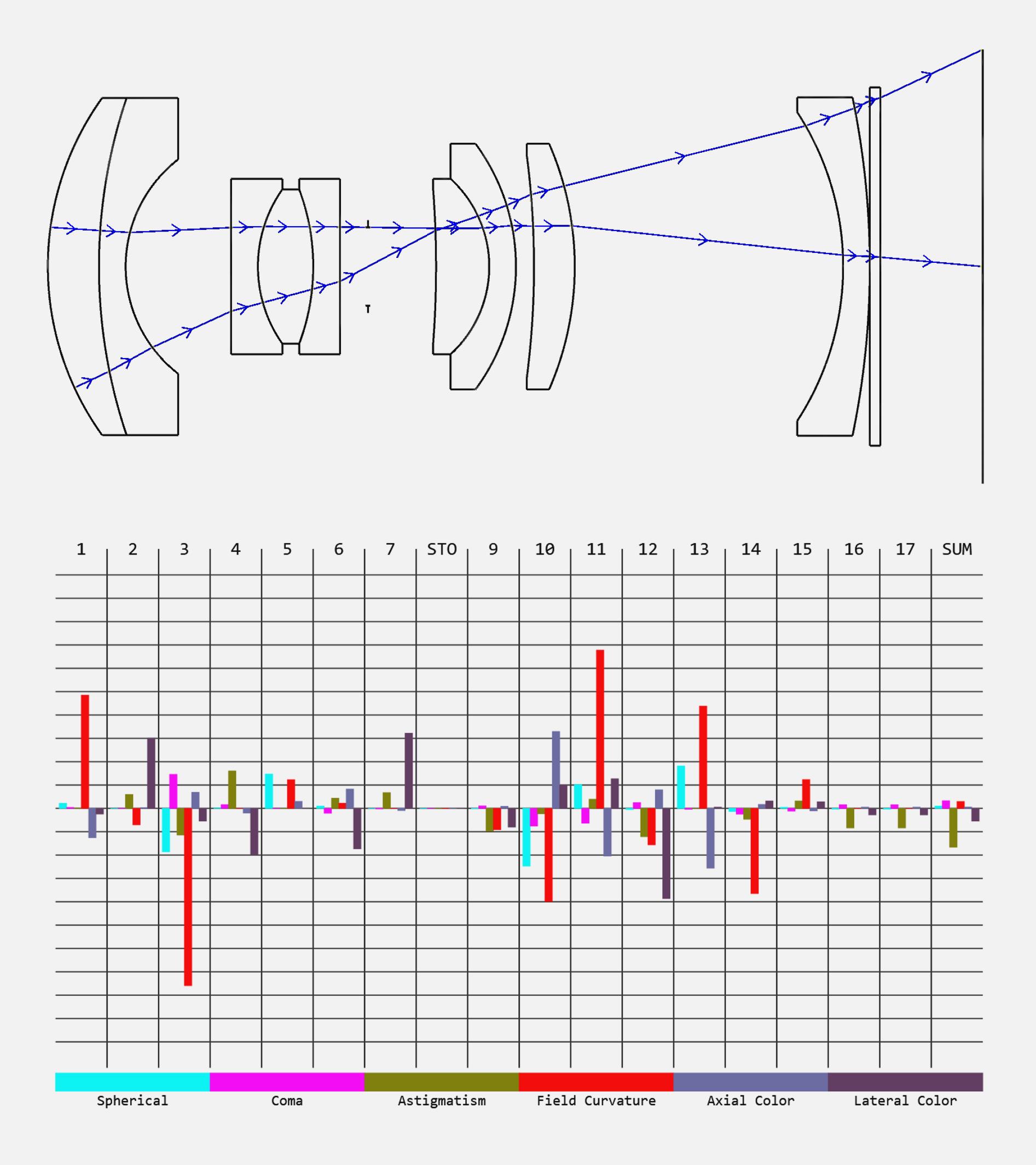

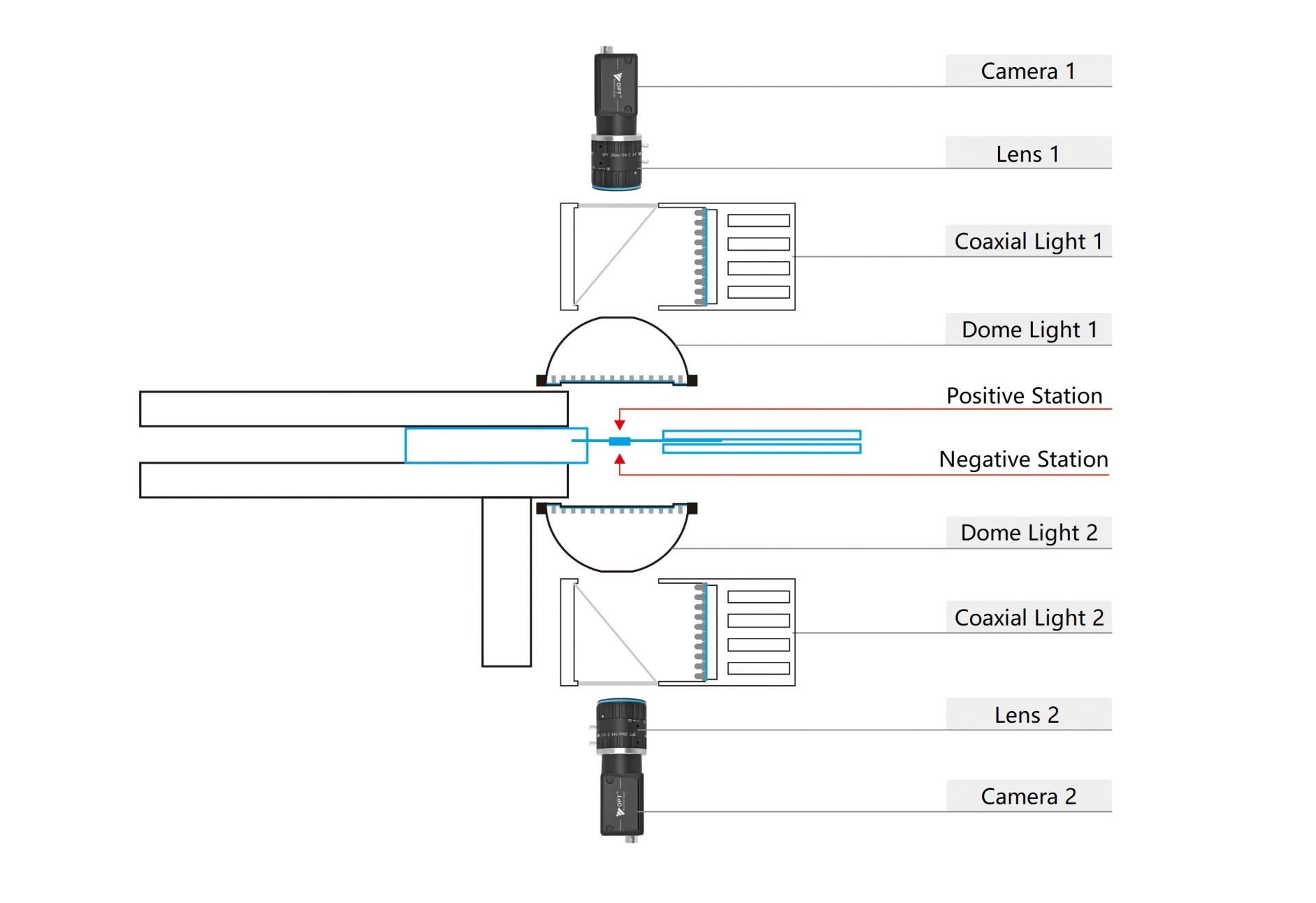

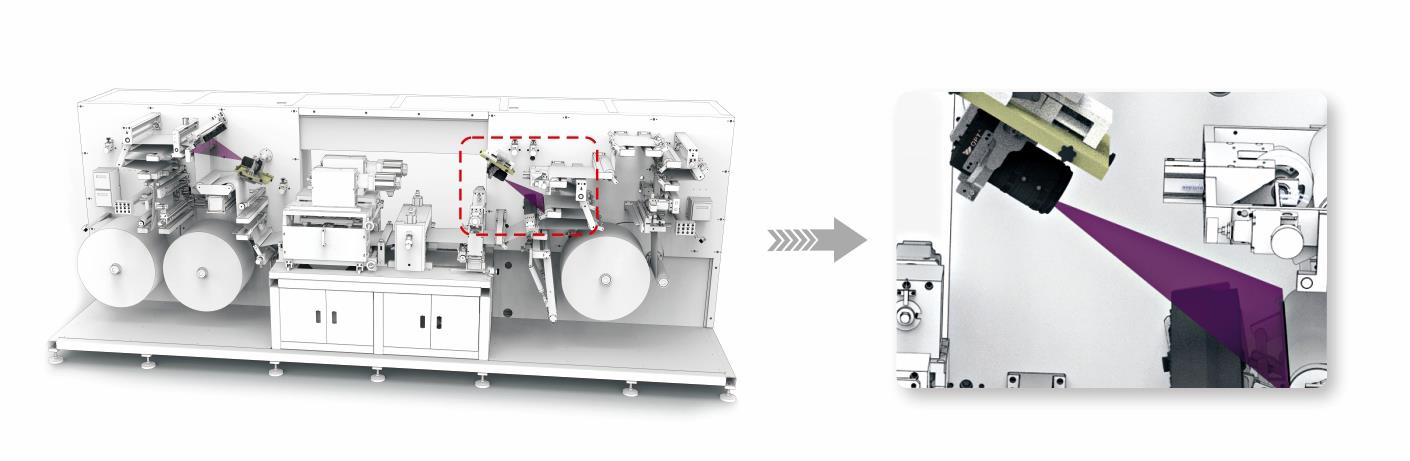

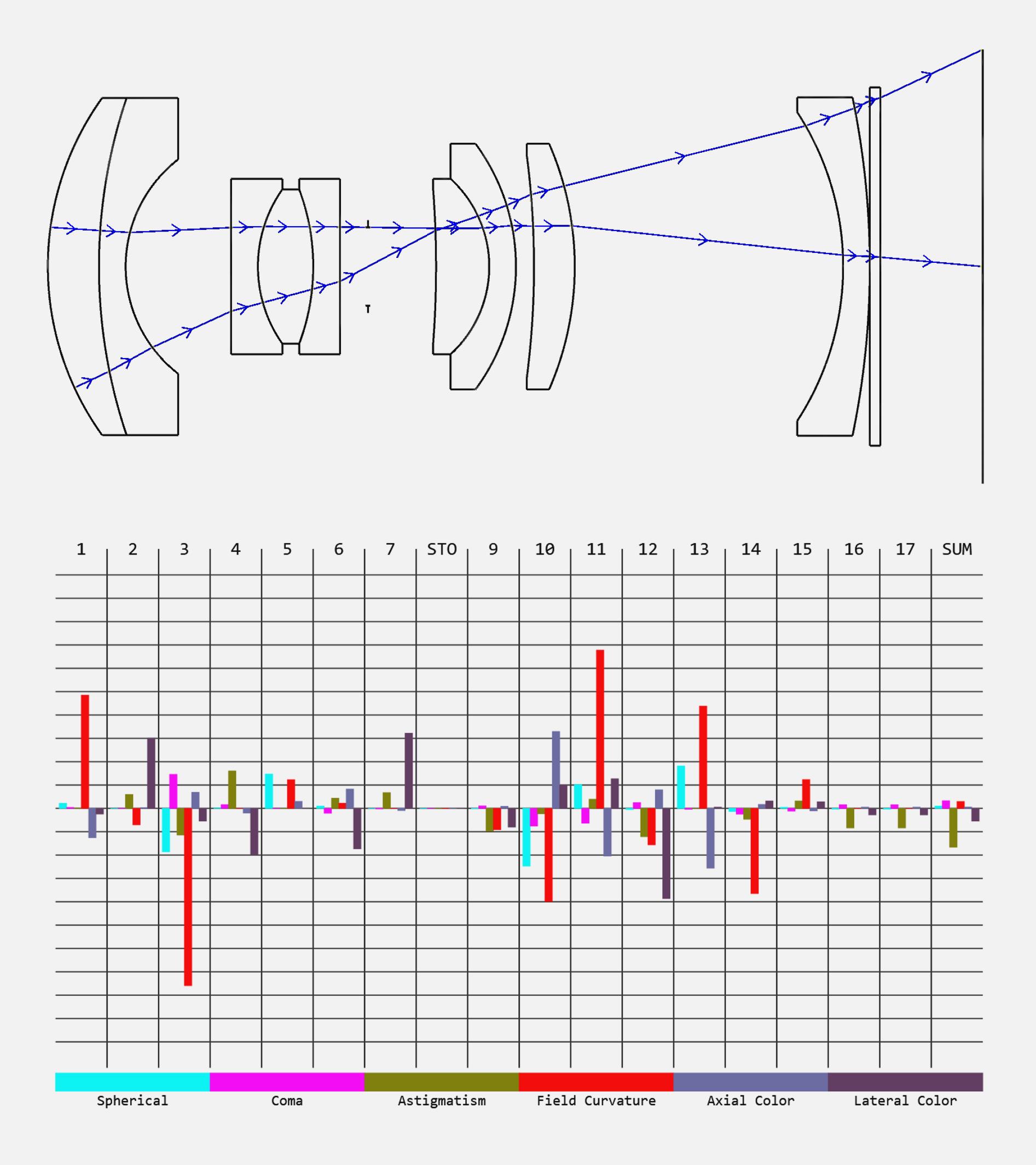

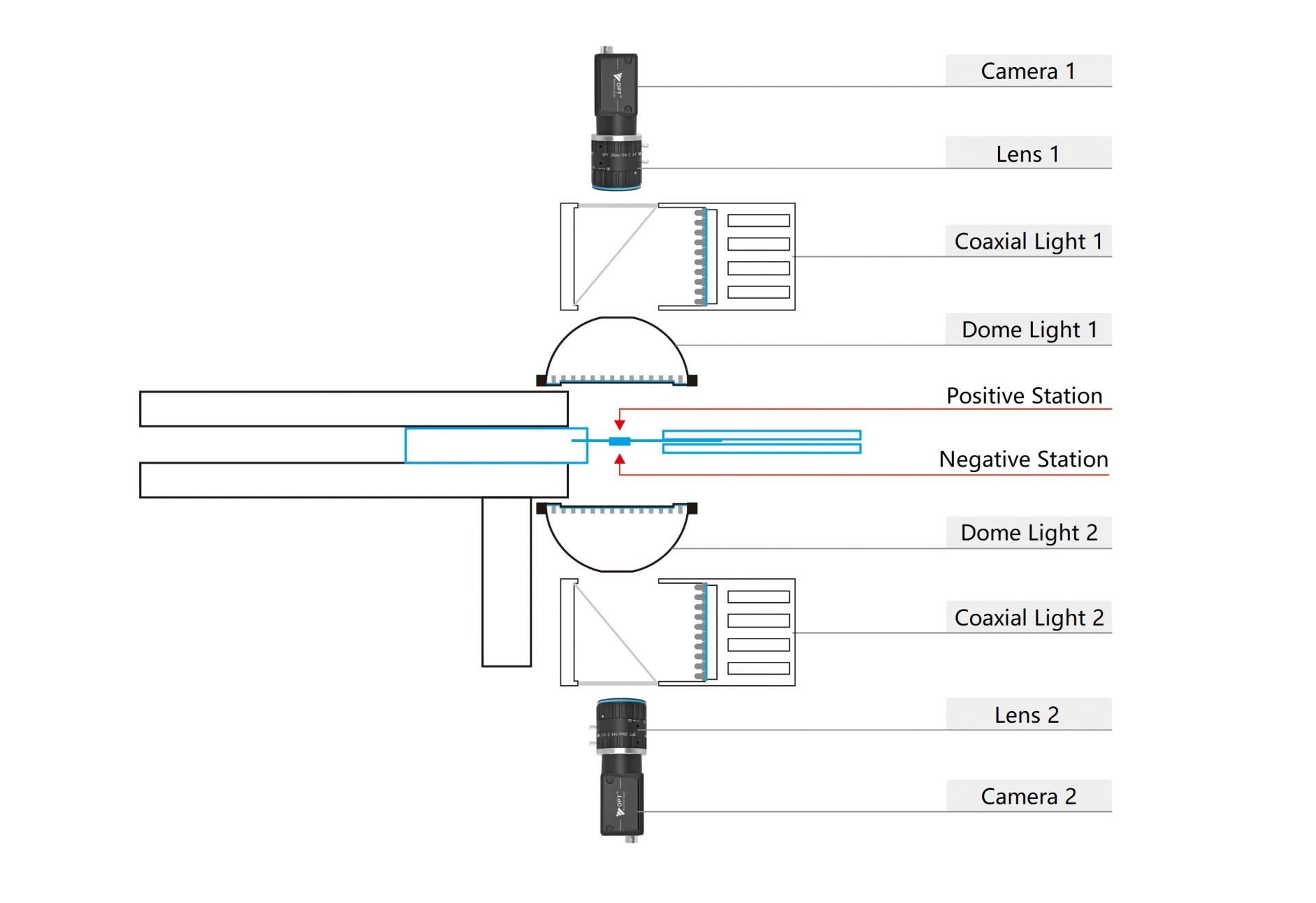

High Resolution Optical Design for Clearer Images

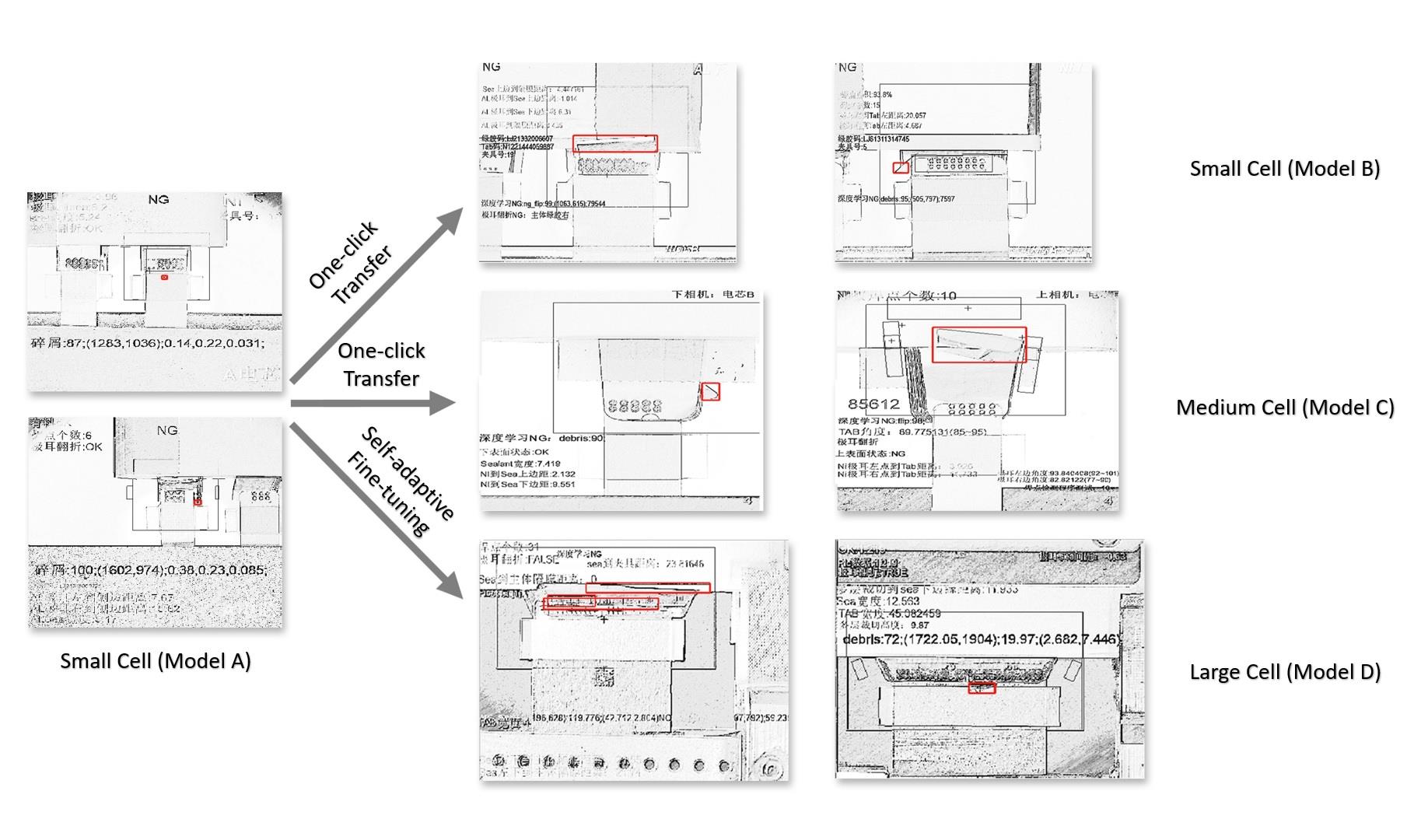

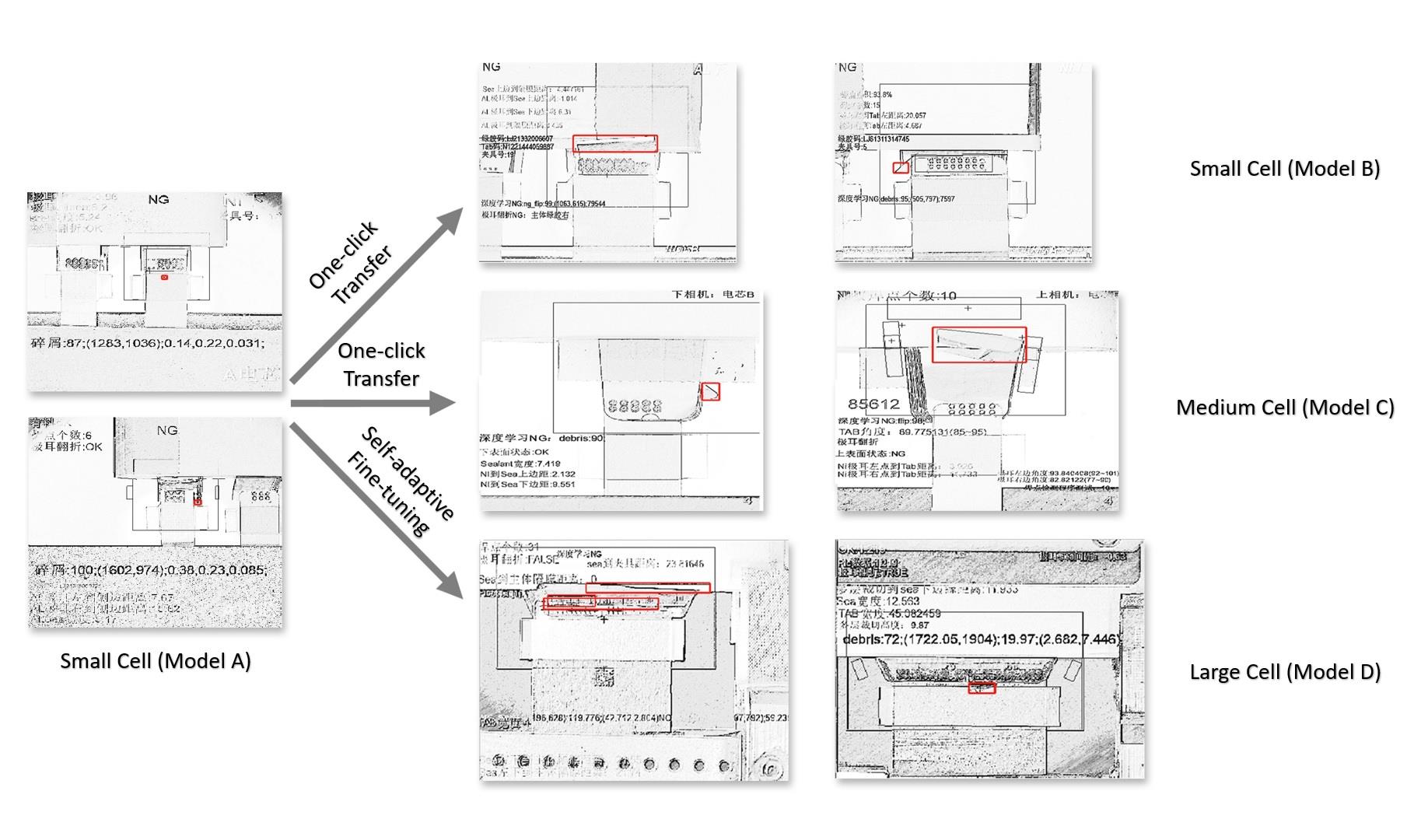

Deep Learning for Precise Extraction of Defect Features

High Resolution Optical Design for Clearer Images

Deep Learning for Precise Extraction of Defect Features