OPT High-Resolution Line Scan Lenses in field of visual Inspection of Lithium Batteries

Over many applications, OPT has thoroughly learned the requirements and difficulties of automatic optical inspection (AOI) of lithium batteries. Based on this experience, a series of line scan lenses have been developed that are particularly suitable for the inspection of lithium batteries. These developments resulted in improvements such as floating focus, automatic detection of lens resolution and optimization of tolerance sensitivity.

A large image circle and high-resolution line scan lenses from OPT offer great advantages in the optical inspection of lithium batteries, such as coating, welding and cold pressing.

In general, efficient quality assurance plays an extremely important role in machine vision. Especially in lithium battery production, a large field of view and high-precision optical inspection are essential.

Line scan lenses from OPT

One example of the need for a large field of view is the burr inspection of electrode sheets. Another is the highly accurate search for extremely small defects in the size range of 1 to 2 µm. There are a number of other demanding optical quality control requirements that are well met by OPT line scan lenses.

OPT has several line scan lens series with large image circle diameters, such as the Coloretto series and the Hawk series. Here, image circle diameters between 30 and 82 mm can be selected. Different magnification ranges allow for different field of view sizes, thus adapting the precision requirements to different processes.

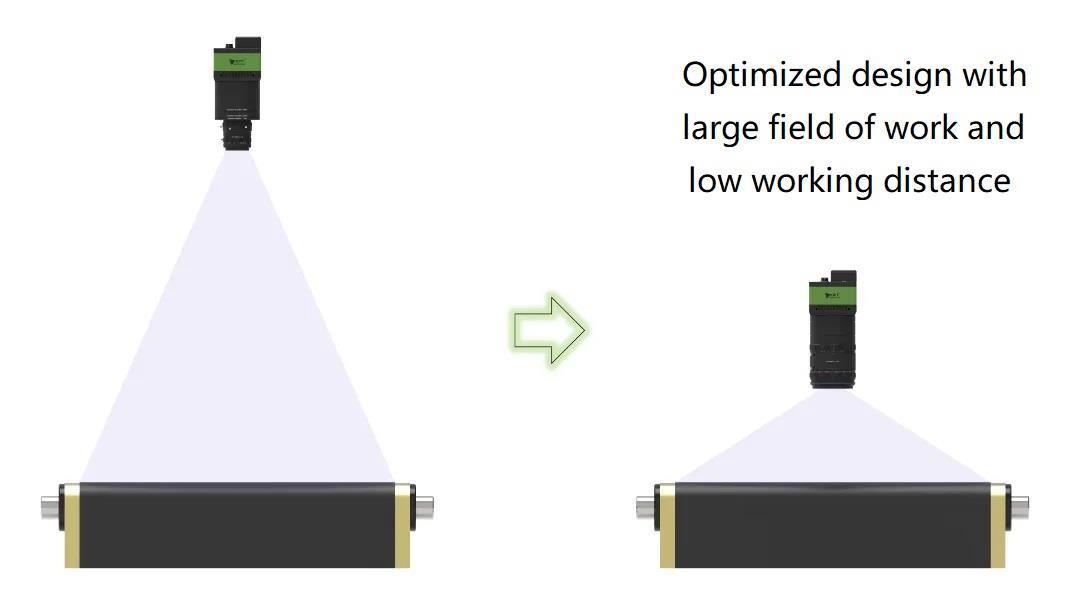

To meet the tight space constraints of lithium battery inspection the most, OPT relies on a large working distance and OPT's proprietary floating focus technology. OPT's line scan lenses are optimized by combined elements and optical back-focus sensitivity to compensate for the contrast between large field of view and short working distance. As a result, a wider range of applications could be achieved relative to the working distance. In addition, the imaging quality is so good that OPT's line scan lenses can be used in many lithium battery testing processes.

High resolution and new technologies improve the entire process from R&D to production

Considering the high standard requirements in the extremely challenging manufacturing of lithium batteries, the line scan lens series developed by OPT were designed and tested with high resolution optical systems. Optimization and quality management of each process are easily accomplished thanks to techniques such as achromatism, low vignetting, tolerance sensitivity optimization, and automatic lens resolution detection. In addition, the image quality has been significantly improved. With these advantages, the improvement to a more productive manufacturing level of lithium batteries is no longer a dream.

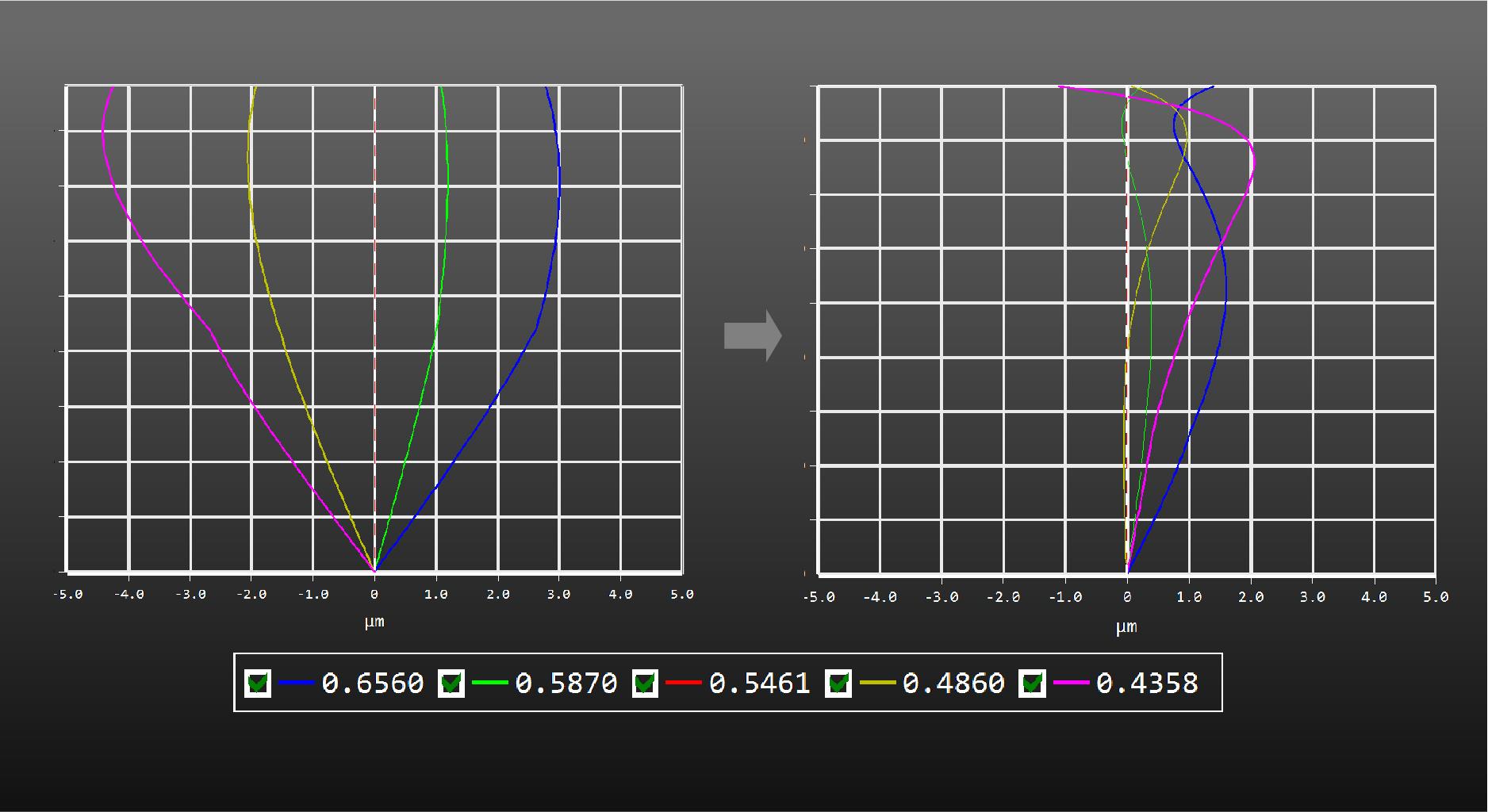

In the design phase of the lenses, the OPT line scan lenses use a wide-spectrum achromatic design. Through the reasonable focal length distribution of each lens, a lens combination of positive and negative refractive power is used to achieve an optimum of chromatic aberration and low image field curvature. The lenses are designed to provide sharp images under various monochromatic and combined illumination conditions in the visible light range.

Wide spectrum and achromatic design

At the same time, the OPT line scan lenses feature a vignetting-reduced design to improve the brightness ratio between the image edge and center and prevent shadows to the image corners. This improves the brightness distribution of the entire test image.

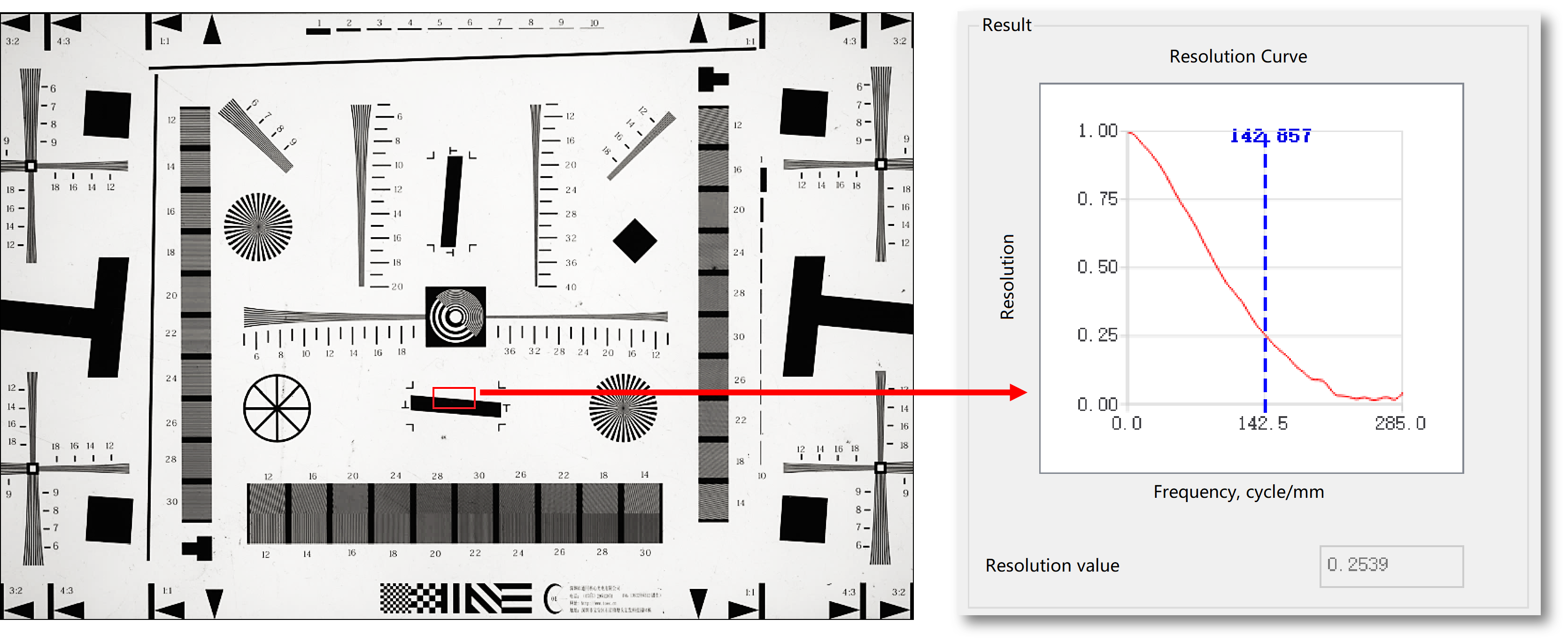

To ensure the quality and durability of the finished lens, OPT uses tolerance sensitivity optimization technology to control the light path. The remaining amount of higher order aberrations are thus kept low. In other words, the performance losses due to manufacturing tolerances in the production and assembly lines are reduced. In the final manufacturing process, OPT also uses automatic lens resolution detection technology for quality control. This prevents human errors such as misjudgments and false positives, and ensures that the final products function properly and are ready for delivery.

Automatic detection of the lens resolution

The integrated microfocus line scan lens structure is widely used in visual inspection of lithium batteries

The OPT line scan lens is equipped with an integrated micro-focus structure, which integrates the focus function directly into the line scan lens body. This will achieve high focusing precision of the lenses, which greatly facilitates installation and commissioning.

The OPT line scan lenses can be applied to many lithium battery inspection processes. Here is one example among them:

In the electrode coating of the batteries as well as the laser cutting process, which includes the measurement of the double-sided coating width as well as the cut electrode tabs and electrode sheets. In this process, the edge sharpness detected by the OPT line scan lenses clearly defines the outer edge contour. The measurement is very accurate, providing more objective data for subsequent tracking.

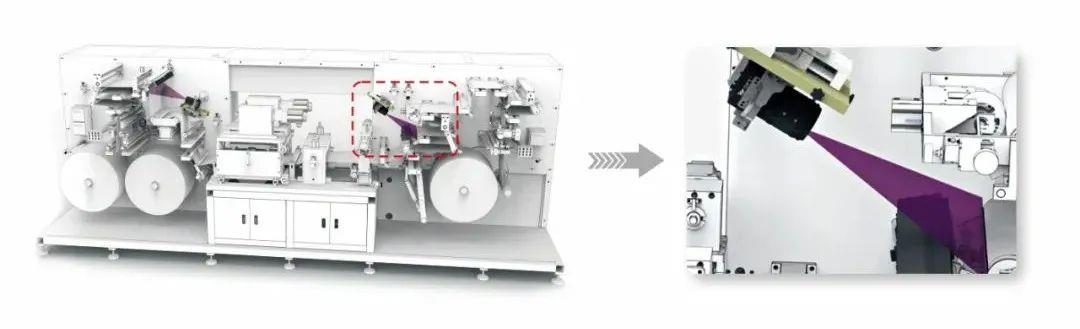

OPT line scan lens in a coating line with lens application

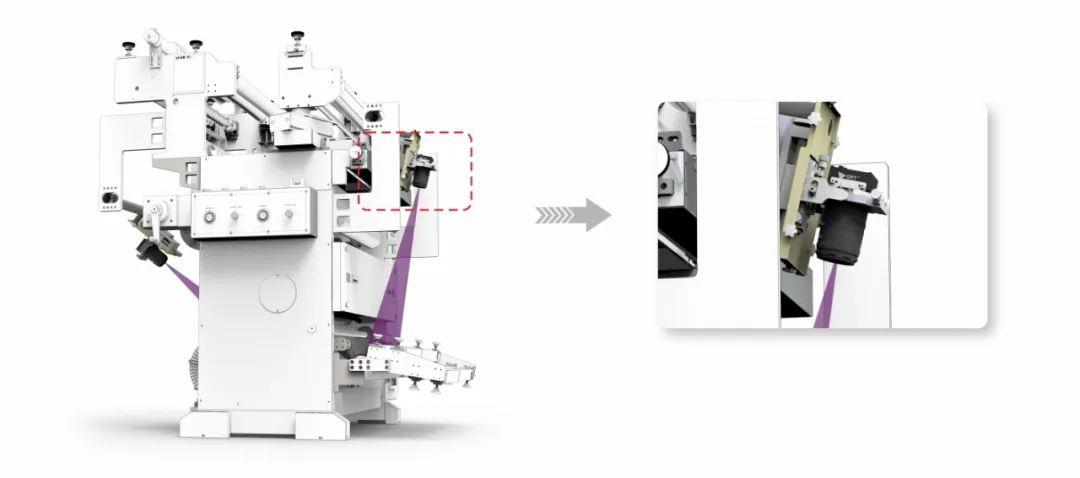

OPT line scan lens in a laser cutting machine

In addition, the OPT products have excellent image quality and can accurately detect various defects in different processes. For example, in cold pressing, the OPT line scan lens can visualize the electrode sheet perforation, bright spot, edge break, powder loss, exposed film, hard block, scratch, blank film, etc. in real time during cold pressing, so that the defect type can then be accurately determined.

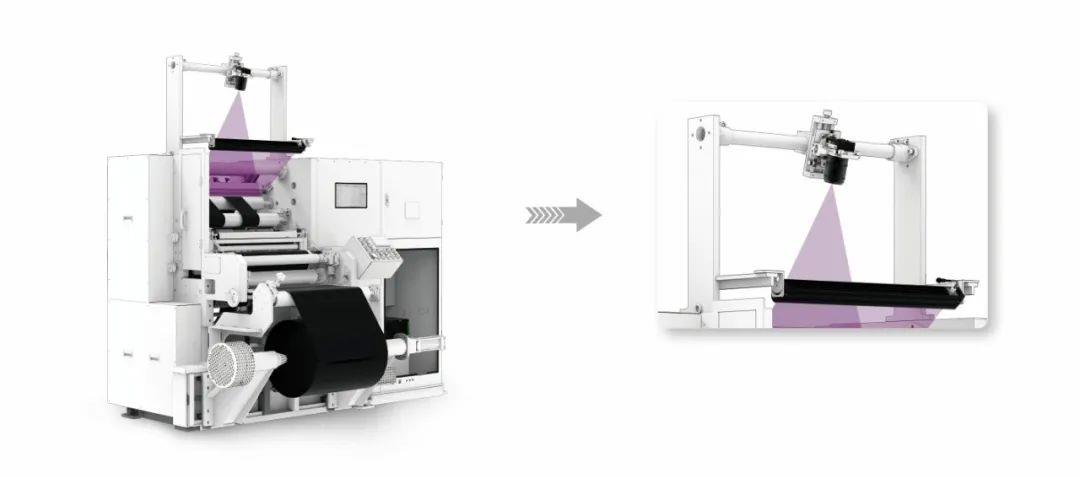

OPT line scan lens in a cold pressing application

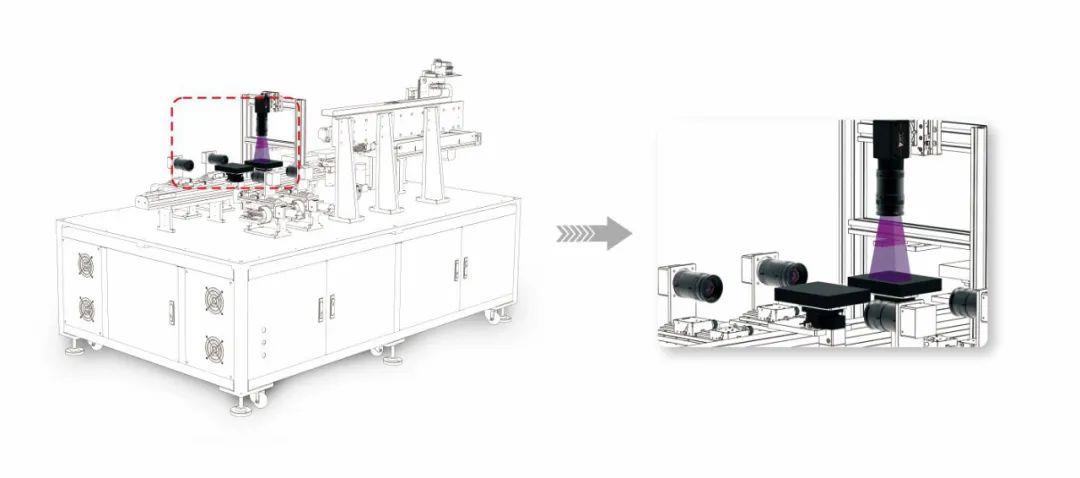

OPT line scan lens in appearance inspection of lithium batteries

EN

EN CN

CN JP

JP