Zero Distortion, Zero Barrier | OPT Releases New Measurement Sensor SmartScan Series

OPT has launched its new measurement sensor, the SmartScan series, specifically developed for 2D-inspection. It is widely used in industries such as aluminum profiles, sheet metal, coil materials, battery manufacturing, PCB boards, garment pattern making, textile materials, and film inspection. The new product is equipped with a built-in Contact Image Sensor (CIS), ensuring distortion-free imaging. Paired with measurement software, importing images requires no programming and automatically generates measurement programs, embodying precision, efficiency, and ease of use.

High-Precision 1:1 Imaging, Zero Distortion

The scanning measurement sensor utilizes a contact image sensor, integrating the light source, lens, and photoelectric conversion chip. By employing a cylindrical lens, it achieves 1:1 imaging between the object and the photosensitive element, avoiding resolution loss caused by image distortion and edge blurring. This also alleviates the burden on subsequent image processing steps.

Not only that, the scanning measurement sensor also offers high resolution, low noise, and a broader dynamic range. Moreover, with its illumination system providing uniform light distribution, it minimally produces reflections, making it particularly suitable for dimensional measurements in the aluminum profile industry, with a resolution of up to 1200dpi.

The scanning measurement sensor can measure widths up to 500mm without its precision being affected by the width. Additionally, it avoids issues like calibration surface tilting and image axis loss or overlap due to inconsistencies in height and angle when stitching cameras together, resulting in higher fidelity in captured images.

Automatic Recognition Program, Efficient Measurement

While ensuring accuracy, the scanning measurement sensor also meets the demands of industrial online inspection. It uses a Cameralink interface in conjunction with a capture card, allowing data transfer speeds of up to 480MB/s. Furthermore, equipped with a 0.1μm high-precision moving platform, it achieves rapid scanning movements.

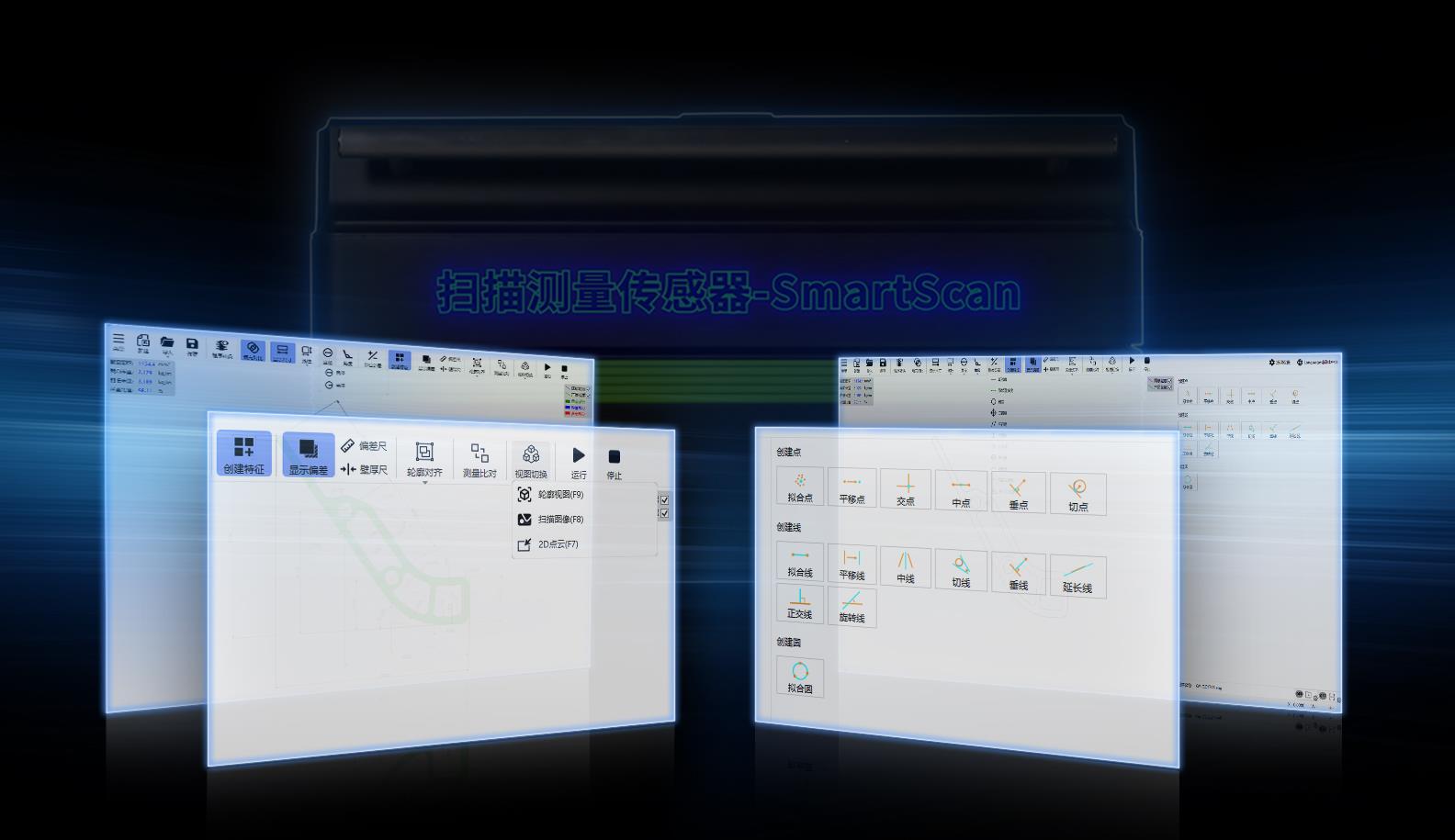

The measurement software that comes with the scanning measurement sensor is developed based on the OPT Smart3 core code, ensuring stable algorithm performance. It supports offline automatic programming, allowing users to automatically recognize CAD drawings with a single mouse click, quickly generate measurement programs, and obtain comprehensive measurement reports.

Intelligent Matching of Measurement Programs

During the measurement process, the scanning measurement sensor can automatically recognize programs, eliminating the need to search for and verify drawings. It also allows for the importation of offline programs for secondary editing. Additionally, it provides various manual measurement elements such as points, lines, and circles, which can quickly assist in the detection of special positions. Moreover, it is compatible with CAD drawing software, obviating the need to switch between software, thus offering convenience and simplicity.

Fully Featured, Zero Barrier to Operation

The scanning measurement sensor is also equipped with more than twenty measurement tools, including wall thickness gauges, meter weight, cross-sectional area, positional accuracy, straightness, contour deviation, etc. It supports comparison filling, graphic matching measurement, and automatic alignment functions, making it easy for even those with no prior experience to operate effortlessly.

Even without CAD drawings and programs, the scanning measurement sensor can still measure dimensions such as distance, diameter, radius, wall thickness, angle, and form and position tolerances for incoming materials. Additionally, it supports reverse engineering, capable of scanning incoming materials to automatically fit them into straight lines and arcs, and exporting them as DXF format files, saving time on manual measurement and drawing output.

Supports Measurement without Drawings & Reverse Engineering

Furthermore, for products with local deformations, the scanning measurement sensor can reposition, intelligently recognize the measurement location, and freely create multiple benchmarks for matching simulations. It analyzes key point deviations from CAD drawings, making measurements more accurate.

Additionally, the scanning measurement sensor does not require an internet connection to operate, ensuring data security. The statistical analysis of measurement data is intuitive, allowing real-time observation of workpiece changes. Reports can be seamlessly uploaded to enterprise ERP systems or WeChat mini-programs, enabling users to check inspection reports at any time.

EN

EN CN

CN JP

JP