VisionChina 2022

The 3-days-long VisionChina 2022 (Shenzhen) exhibition has come to an end on November 17. As a machine vision components supplier for factory automation, OPT has showcased both software and hardware products as well as machine vision solutions via smart code readers, 3D and 2D inspections. The applications in lithium batteries and 3C manufacturing industries were the highlights of the exhibition.

The Crowd at VisionChina 2022 (Shenzhen)

Besides the machine vision component products such as industrial cameras, lenses and light sources, OPT also focused on the application of 3D machine vision inspection in industries such as lithium batteries, 3C, etc.

Machine Vision Hardware Products

Thickness Measurement of Laptop Keyboard

For example, OPT’s 3D Laser Profilers are the main products used in the solutions to the appearance quality inspection of lithium battery for top panel, welded seam, sealing pin, blue PET protective film, etc. The 3D laser profilers use the telecentric optical path design to avoid from the shadowed areas such as vignette effects and blind spot. At the same time, the images undergo binarization via vision software and algorithm of welding defect inspection, which greatly enhance the inspection efficiency and accuracy. This helps to identify the area of welding defects at ease.

Appearance Quality Inspection for Welded Seam and Blue PET Film of Lithium Batteries

OPT has demonstrated the applications such as glue bead inspection. For example, electronic components, printed circuit boards (PCB), integrated circuits (IC), etc. would require to join and fix together using glue sealant. This is always the challenging part for machine vision inspection due to the transparent or translucent effect which can be hardly detected. Using the high dynamic algorithm, the edge contour of the glue can be detected with an accuracy of micron level. Combination with the operator block of the vision software, the height and width of the glue beads can be calculated to determine if there is any absence of glue bead.

Glue Bead Inspection

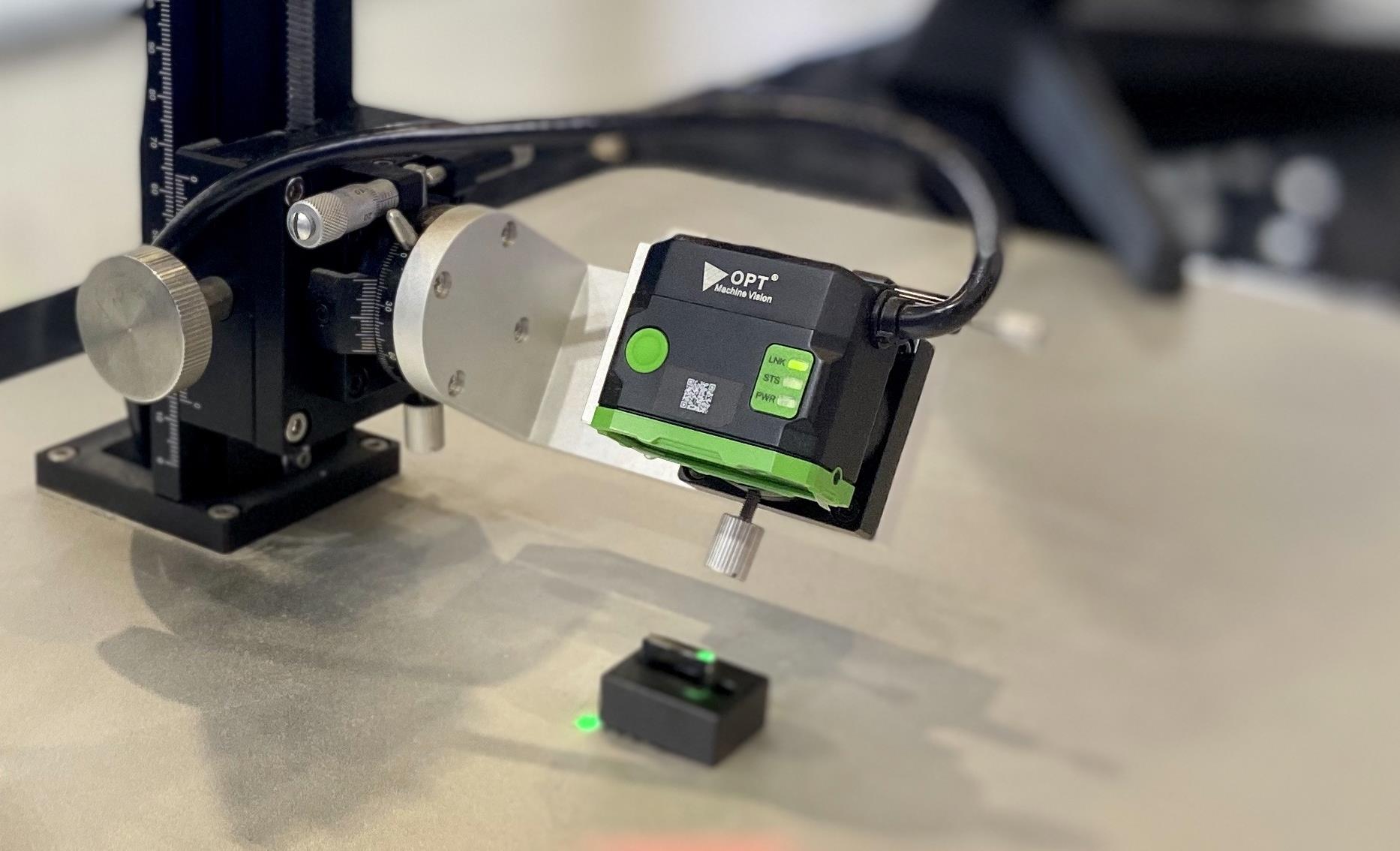

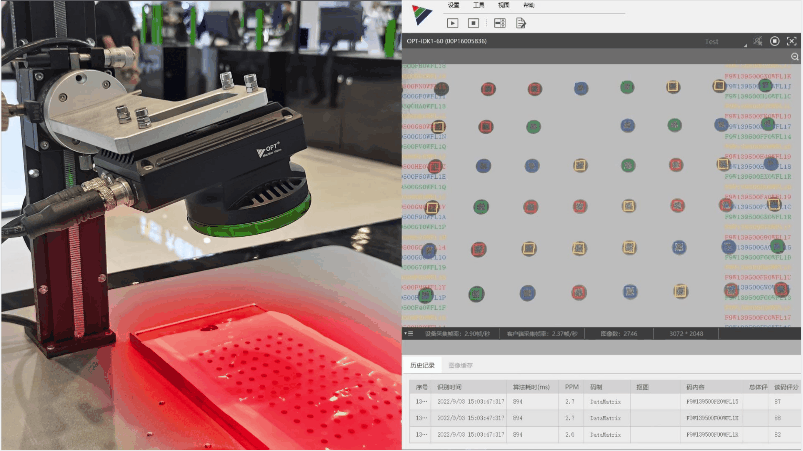

Industrial barcode reading has been widely used in tracking and management of entire life cycle from the supply chain to the production of end product. This is important to achieve quality control. OPT has unveiled a number of code reading solutions including reading distorted and reflected barcodes, data matrix (DM) codes, etc., basically covering different code reading requirements of various industries.

Reading DM Code on Smartphone Camera (Product)

Reading Barcode on Curved Surface

Positioning Inspection of Smartphone Camera Modules

Quality Inspection of Laptop Keyboard

The Crowd at VisionChina 2022 (Shenzhen)

Last but not least, OPT also demonstrated the inspection based on Deep Learning software such as quality inspection of LCD panel. The combination of dot matrix lighting and industrial-grade AI vision software allows a full inspection of LCD panel to detect irregular or tiny defects.

EN

EN CN

CN JP

JP