Smart3 Machine Vision Software

Product introduction

Software Products

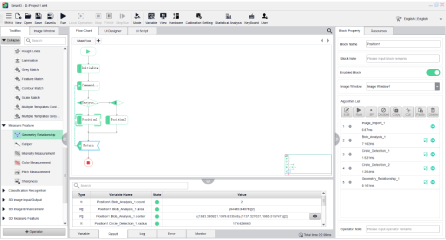

OPT offers products such as vision software and vision controllers, including:Smart3 Vision Software: With visualized process editing, it enables users to quickly implement vision projects through parameter configuration, without requiring any programming.

Smart3 Machine Vision Software

- A full-featured platform (2D, 3D, and machine learning) that covers all vision scenarios on a single platform.

- No manual programming is required, it is simple and easy to use, quick to get started, able to quickly respond to requirements and shorten the project development cycle.

- Customized interfaces and humanized interactive designs, which allows for quickly creating interface layouts for customer projects through drag-and-drop functionality, meeting customer requirements for design preferences and usage habits.

- Supports mainstream industrial camera brands and the GeniCam standard protocol.

- Supports mainstream hardware communication and protocols, including robotic arms, PLCs, motion modules, I/O expansion cards, and more.

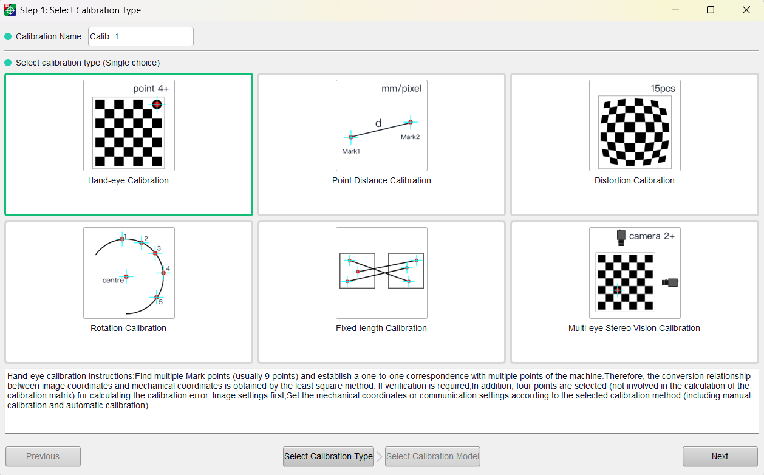

- Supports multiple calibration methods, covering standard calibration scenarios and enabling quick customization for specific calibration requirements.

- Supports online debugging, allowing adjustments to vision parameters during operation without halting production, ensuring optimal inspection results.

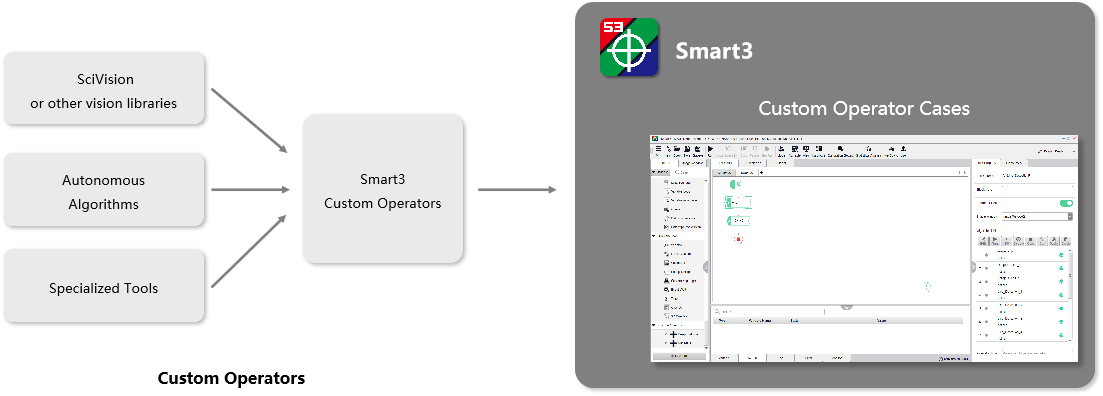

- Supports secondary development based on user-defined requirements, with COM and .NET interface technologies enabling compatibility with multiple programming languages such as C#, C++, Python, and VB.

- Provides extended algorithm development interfaces, allowing users to independently develop and integrate custom algorithms and specialized tools for use as foundational Smart3 tools.

- Supports multiple platforms, including macOS, Windows, and Linux

Comprehensive Vision Platform

A single platform covering all vision scenarios

| 2D Function | 3D Function | Machine Learning Function |

| Image preprocessing, matching and positioning, geometric measurement, defect detection, etc. | Algorithms for differential defect detection, unordered sorting and picking, stereo pose matching, adhesive path detection, etc. | Semantic segmentation, object recognition, image classification, character recognition, instance segmentation, and more. |

|

|

|

Simple and user-friendly, with quickly response to requirements to shorten project development cycles

Vision Graphical Editing Customizable UI Interface Drag-and-Drop Layout Functionality

| Smart3 Flow Diagram | Customizable UI Interface |

|

|

|

Sub-processes enable more intuitive multi-station implementation

Enabling the main process more concise and enhancing program readability.

|

|

|

Supports online import of specified images for retrospective analysis.

30+ Industries 5000+ Cases

- Specifications

- Downloads

EN

EN CN

CN JP

JP