OPT Releases the 3D Laser Profiler LPF Series

New 3D Laser Profiler-the LPF series is officially released by OPT. With a newly upgraded optical structure and embedded algorithms, it can measure any contour line of objects within the depth of field and output ultra-high-resolution point cloud and depth maps in real-time.

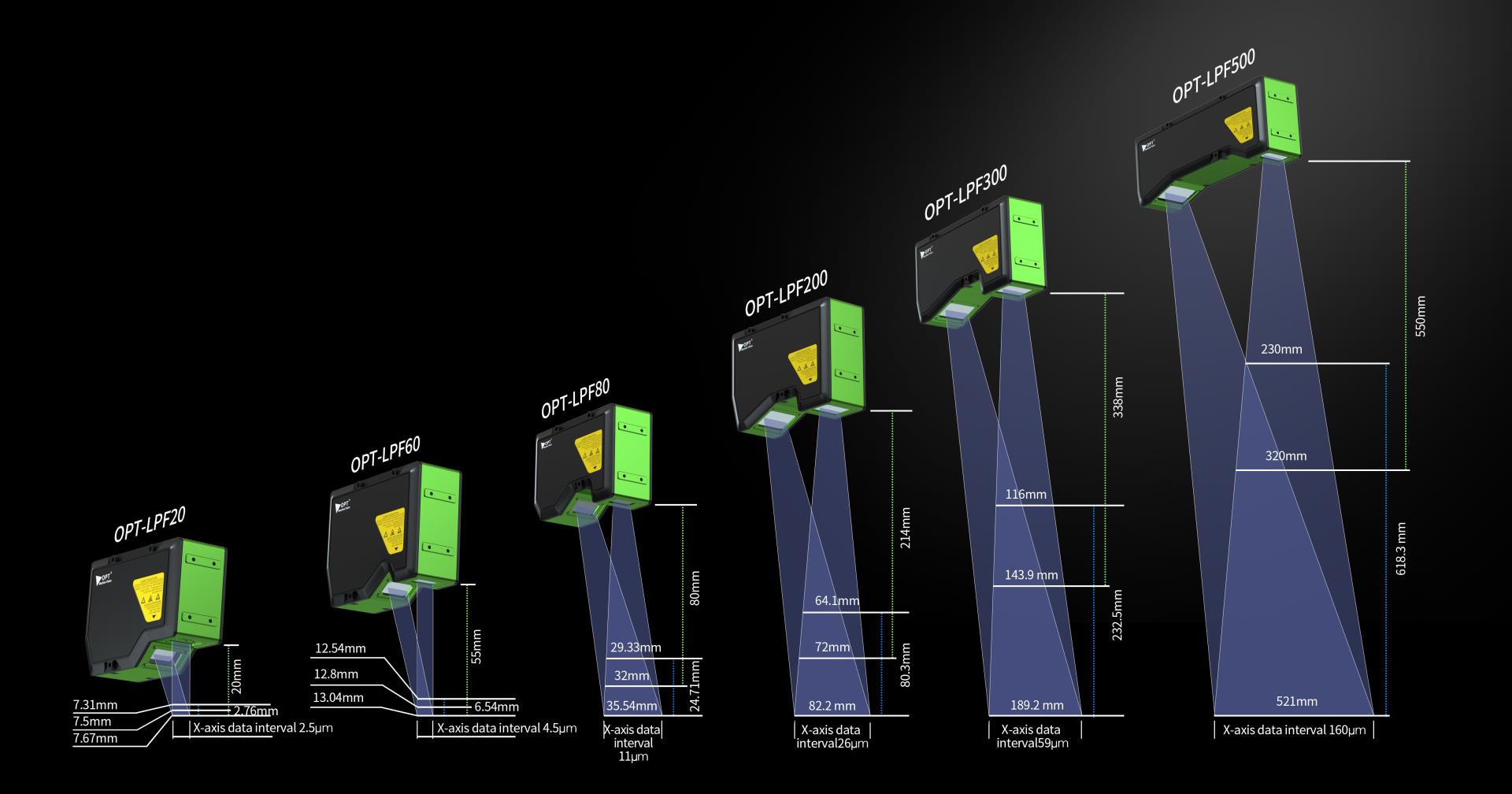

The new release includes six models, with X-axis widths ranging from 7.677mm to 521mm and Z-axis repeatability reaching up to 0.1μm. These sensors meet various field of view and precision requirements for visual inspection, making them suitable for industries like 3C electronics, automotive manufacturing, and hardware.

Ultra-High Precision, Detects Minute Changes

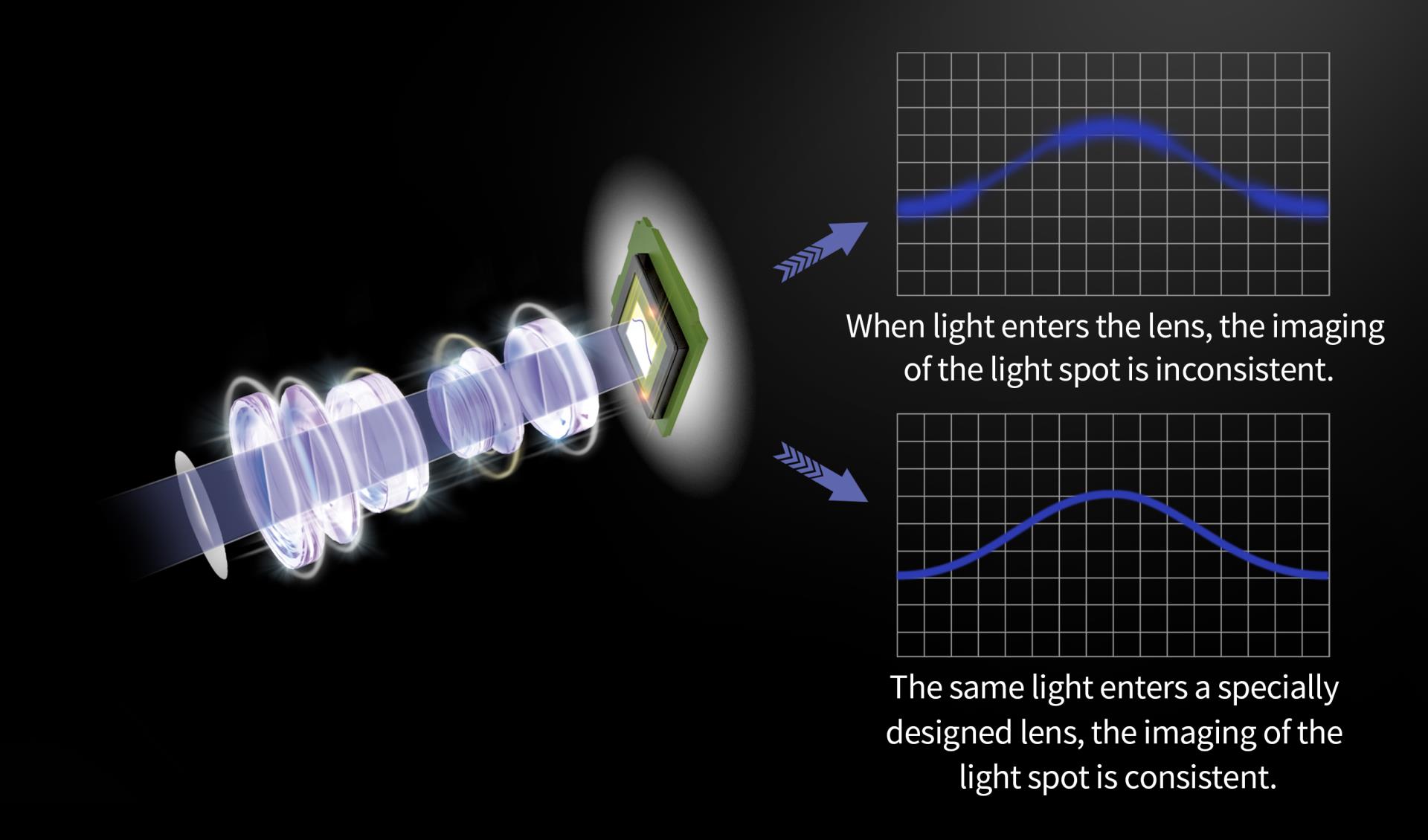

The new series of 3D laser profilers use a high-precision blue laser with a narrow linewidth design to improve resistance to environmental interference and versatility. The laser's adaptive brightness adjustment automatically optimizes brightness based on different workpieces, achieving high-quality contour acquisition. With 3200 contour points, the higher imaging precision accurately reproduces the target object's contour, detecting even minor defects like small dents and bumps. OPT also employs a unique optical design with larger aperture lens modules than before, significantly increasing light intake and effectively suppressing diffuse reflections on the target's surface, ensuring consistent imaging across different height ranges.

High Precision in Z-Axis Measurement

In addition to achieving ultra-high precision in the X-axis, OPT has optimized the measurement precision and range in the Z-axis. This allows for compatibility with workpieces of greater height variations while maintaining the same X-axis scan width, suitable for various product inspection applications.

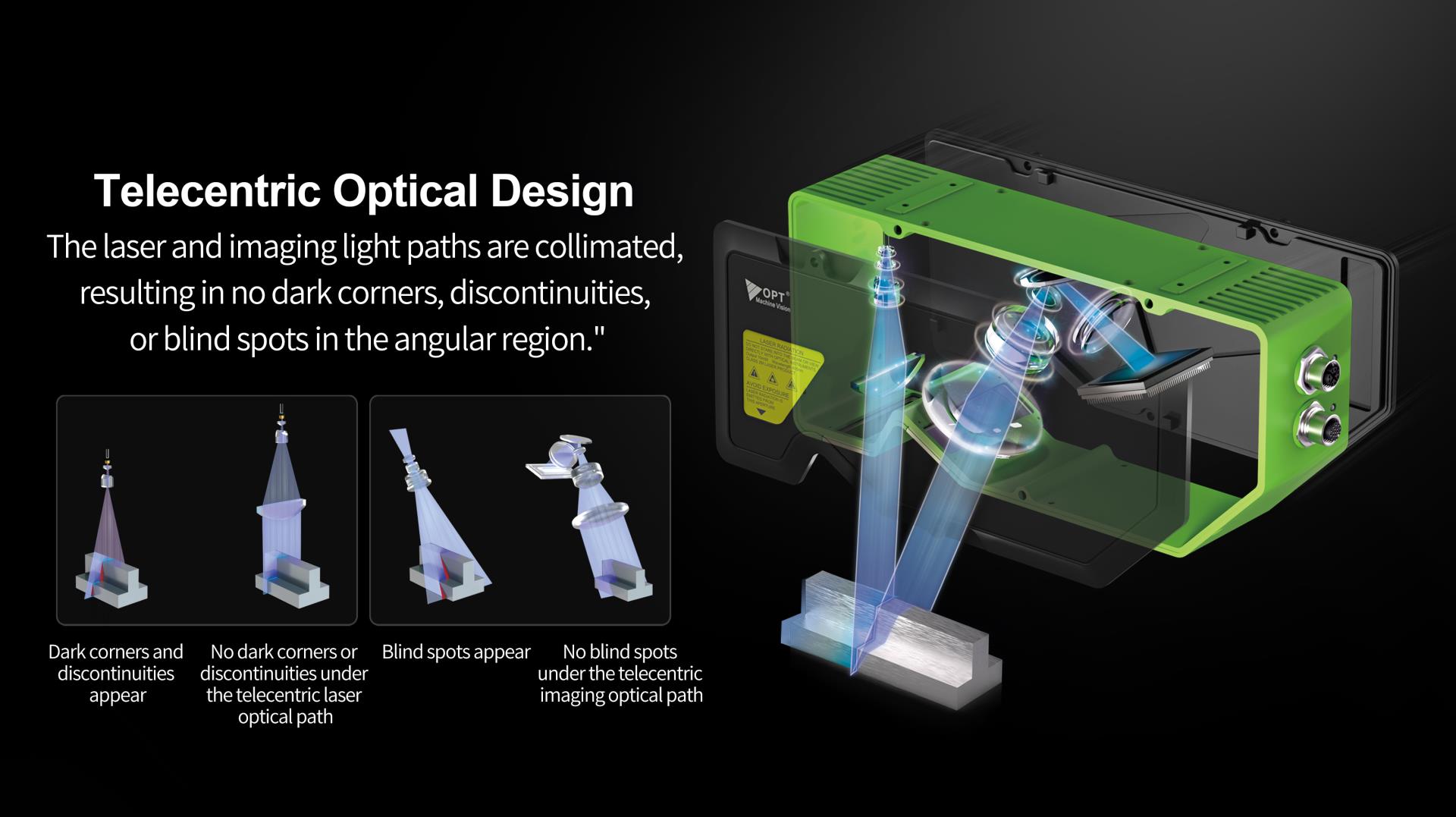

Dual Telecentric Optical Path Design, No Blind Spots

OPT 3D laser profiler uses a dual telecentric optical path design, utilizing Powell prisms and cylindrical lens combinations to collimate the laser, effectively avoiding interruptions and blind spot interferences caused by the angle between the laser and lens field of view, achieving full-coverage detection. This is particularly beneficial for inspecting products with height variations, such as injection-molded parts and connectors. OPT 3D laser profiler ensures blind-spot-free imaging in angular or steep areas, providing more comprehensive inspection.

Rich Algorithm Features, Enhanced Detection Efficiency and Accuracy

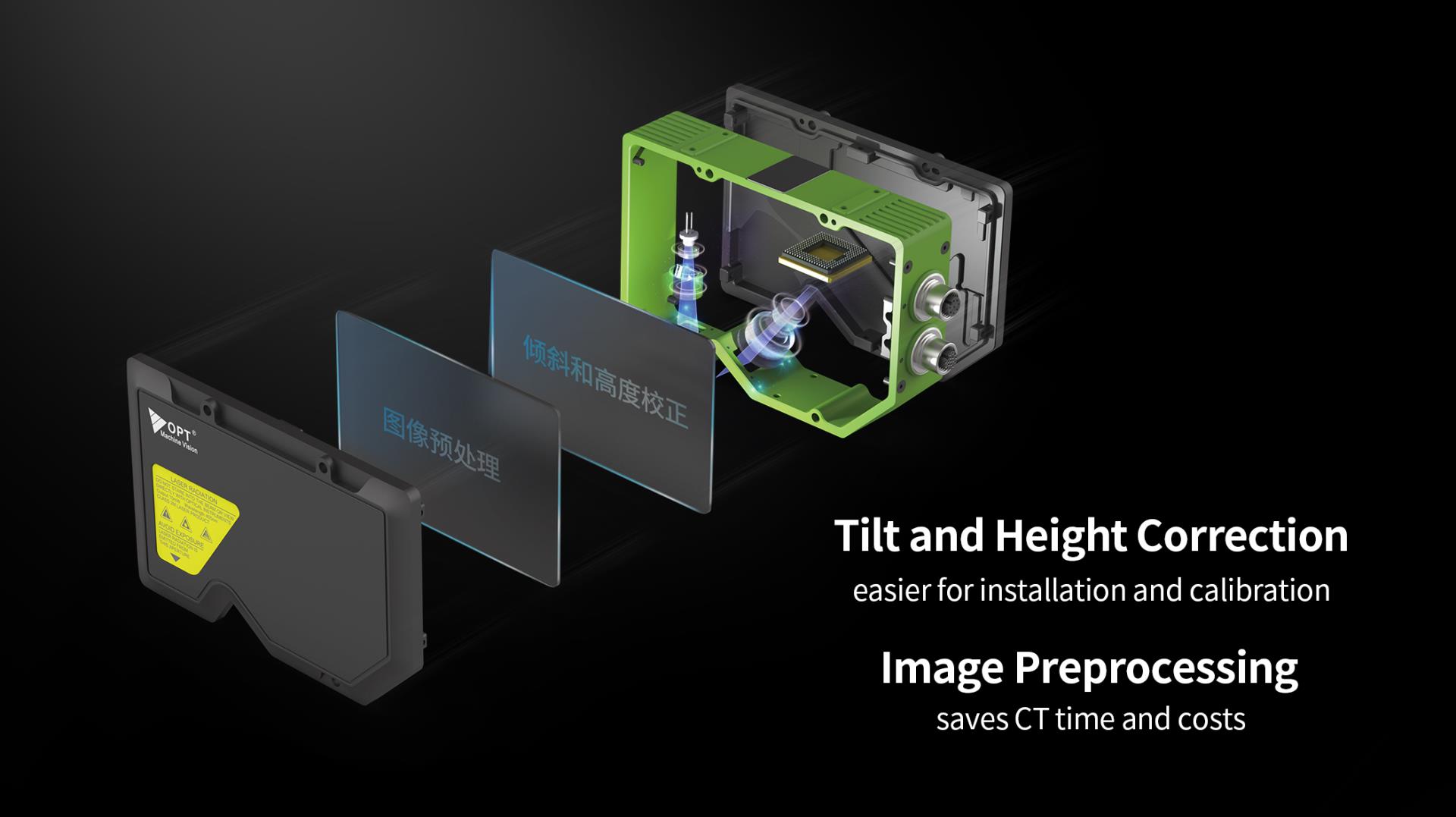

Leveraging FPGA-based edge computing technology, OPT 3D laser profiler utilizes parallel processing capabilities for high-speed scanning. It integrates tilt, height correction functions, and image preprocessing algorithms, making installation and calibration quicker and easier, saving CT time.

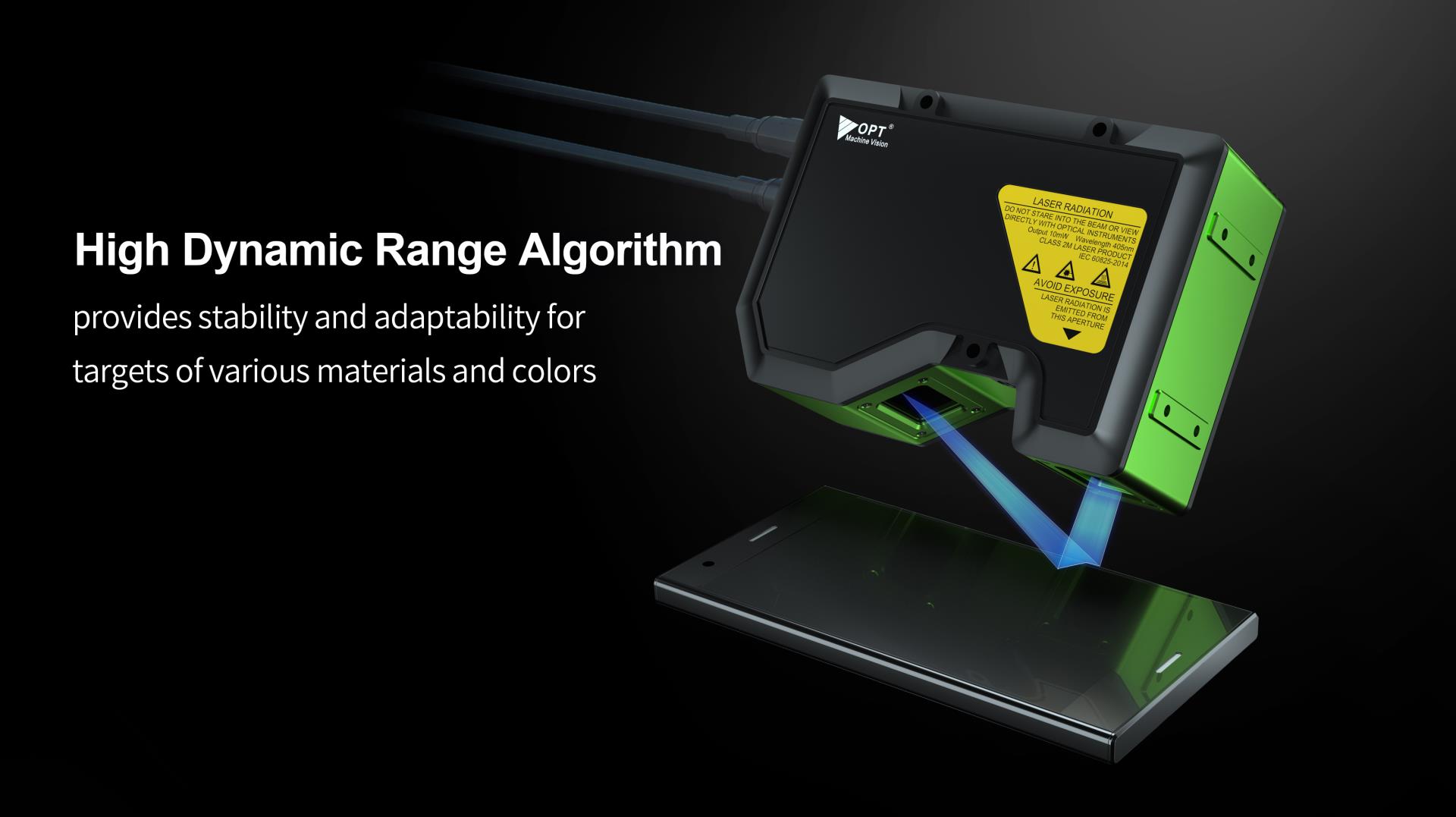

OPT 3D laser profiler also features high dynamic algorithms to better handle various targets. Even with different materials and colors, a single shot can measure them simultaneously. For example, during smartphone assembly, where the reflectance of the phone’s CG frame and screen module surface differs, OPT 3D laser profiler can precisely detect assembly flatness using adaptive dynamic range.

Additionally, OPT 3D laser profiler offers a diverse SDK for easy secondary development. It also supports Smart3 vision software, equipped with specialized 3D high-precision measurement and inspection algorithms, allowing easy use without programming and significantly shortening project cycles.

EN

EN CN

CN JP

JP